In today's demanding industrial landscape, the need for reliable power is paramount, and 500kVA industrial generator sets stand as robust solutions for ensuring business continuity. However, the substantial power they generate often comes with a significant drawback: noise. Industrial generators, especially those in the 500kVA range, can produce considerable noise levels, which, if left unaddressed, can lead to a multitude of problems. These issues range from regulatory compliance and worker discomfort to broader environmental concerns. Therefore, understanding and implementing effective noise reduction strategies is not just a matter of best practice, but often a critical operational necessity. For businesses relying on these powerful machines, exploring and understanding the various noise reduction enclosure options is a crucial step towards creating a more productive, compliant, and harmonious working environment. This article delves into the diverse world of noise reduction enclosures for 500kVA industrial generator sets, exploring the options available and the factors to consider when making the right choice for your specific needs.

The Critical Importance of Noise Reduction for Industrial Generators

The issue of noise emanating from industrial generator sets is not merely an annoyance; it's a multifaceted problem with tangible consequences. Excessive noise pollution can have a detrimental impact on worker health and productivity. Prolonged exposure to high noise levels can lead to hearing loss, increased stress, and reduced concentration, all of which negatively affect employee well-being and operational efficiency. Furthermore, many regions and industries are governed by strict noise level regulations. Failing to comply with these regulations can result in hefty fines, operational delays, or even forced shutdowns. Beyond the immediate workplace, excessive generator noise can also disturb surrounding communities, leading to complaints and strained relationships with neighbors. In environmentally sensitive areas, noise pollution can disrupt local ecosystems and wildlife. Therefore, investing in effective noise reduction for 500kVA industrial generators is not just about creating a more pleasant environment; it's about ensuring regulatory compliance, protecting employee health, maintaining good community relations, and demonstrating environmental responsibility. It's a proactive approach that mitigates risks and fosters a sustainable and responsible operational footprint. Ignoring generator noise is simply not a viable option for any organization committed to responsible and efficient operations.

Understanding the Sources of Generator Noise

To effectively tackle generator noise, it's crucial to first understand where it originates. Industrial generator sets, particularly those in the 500kVA range, are complex machines with multiple noise-generating components. The primary source is undoubtedly the engine itself. The combustion process, mechanical movements of pistons and crankshaft, and the engine's cooling fan all contribute significantly to the overall noise profile. Exhaust systems are another major culprit. The rapid expulsion of exhaust gases creates high-frequency noise that can travel considerable distances. The alternator, responsible for generating electricity, also produces noise due to its rotating components and electromagnetic activity. Furthermore, vibrations from the engine and alternator can be transmitted through the generator's frame and surrounding structures, effectively turning them into soundboards that amplify the noise. Even the cooling system, essential for preventing overheating, can add to the noise level through fan operation and airflow. Understanding these diverse sources of noise is the first step in designing and implementing effective noise reduction strategies. It allows for a targeted approach, addressing each noise source individually or collectively to achieve optimal sound attenuation. By pinpointing the origins of the noise, we can then select the most appropriate enclosure options and materials for a 500kVA industrial generator set.

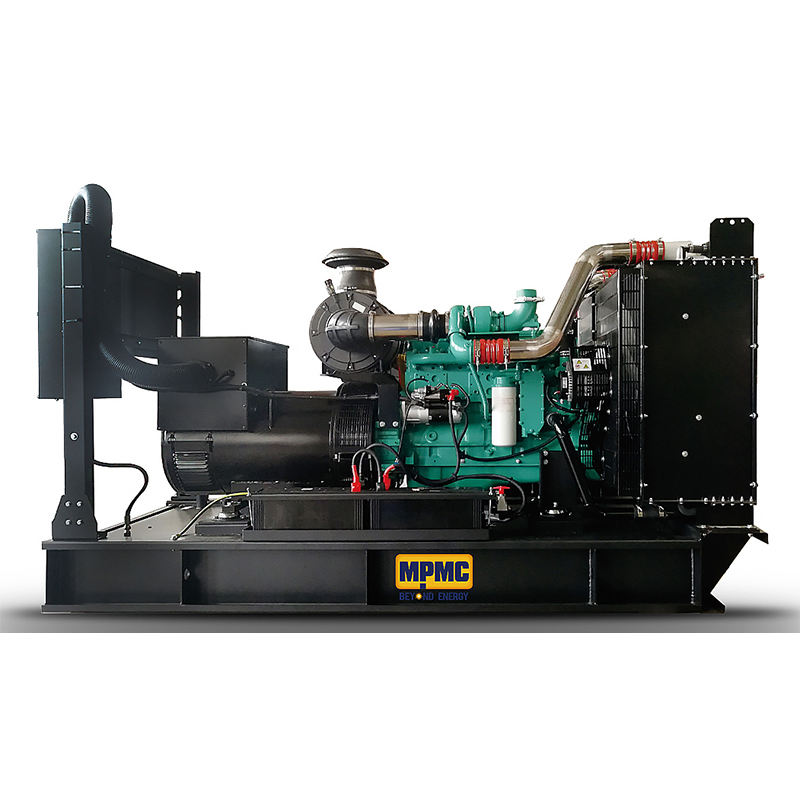

Introducing Noise Reduction Enclosures: The Primary Solution

For 500kVA industrial generator sets, noise reduction enclosures stand out as the most comprehensive and effective solution for mitigating noise pollution. These enclosures are specifically engineered structures designed to surround the generator set and significantly reduce the amount of noise that escapes into the surrounding environment. Think of them as soundproof rooms built around the generator. They work on several key principles of acoustics. Firstly, they act as a physical barrier, preventing sound waves from directly propagating outwards. Secondly, they incorporate sound-absorbing materials, often lining the interior walls, which dampen and reduce the intensity of sound waves within the enclosure. Thirdly, they are designed to minimize sound leakage through openings, such as ventilation inlets and outlets, cable entry points, and access doors, often employing labyrinthine designs and acoustic seals. Noise reduction enclosures are not simply boxes; they are carefully engineered systems that take into account factors like ventilation (to prevent overheating), accessibility for maintenance, and durability to withstand harsh industrial environments. They represent a significant investment in noise control, but the benefits in terms of noise reduction, regulatory compliance, and improved working conditions are often substantial and justify the cost. For organizations serious about managing generator noise, enclosures are the cornerstone of a successful noise reduction strategy.

Types of Noise Reduction Enclosures: Weatherproof vs. Sound Attenuated

When considering noise reduction enclosures for a 500kVA industrial generator set, it's important to understand the different types available, each designed to address specific needs and environments. One fundamental distinction is between weatherproof enclosures and sound attenuated enclosures. Weatherproof enclosures, as the name suggests, primarily focus on protecting the generator set from the elements – rain, snow, dust, and extreme temperatures. While they often offer some degree of noise reduction simply by virtue of being an enclosed structure, their primary purpose is environmental protection, not optimized sound attenuation. They are typically constructed from materials like steel or aluminum and are designed to be robust and durable. Sound attenuated enclosures, on the other hand, are specifically engineered for maximum noise reduction. They incorporate advanced acoustic materials and design features to significantly reduce noise levels. These enclosures often feature thicker walls, specialized sound-absorbing linings, and more sophisticated ventilation and access door designs aimed at minimizing sound leakage. While sound attenuated enclosures also offer weather protection, their core function is noise control. The choice between weatherproof and sound attenuated enclosures depends on the specific priorities of the application. If weather protection is the primary concern and moderate noise reduction is acceptable, a weatherproof enclosure might suffice. However, if significant noise reduction is paramount, a dedicated sound attenuated enclosure is essential. It's worth noting that some enclosures can offer a combination of both robust weather protection and substantial sound attenuation, representing a balanced solution for demanding applications.

Exploring Advanced Sound Attenuated Enclosure Options

Delving deeper into sound attenuated enclosures, we find a range of options designed for varying levels of noise reduction and specific operational requirements. Within this category, you might encounter terms like "silent" or "super silent" enclosures. These typically refer to enclosures that offer exceptionally high levels of noise attenuation, often achieving noise reductions of 20-30 dBA or even more compared to an unenclosed generator set. These advanced enclosures often employ multi-layered wall construction, incorporating different types of sound-absorbing and sound-blocking materials. For example, they might use a combination of dense mineral wool for sound absorption and heavy gauge steel for sound blocking. The design of ventilation systems in super silent enclosures is also more sophisticated, often utilizing baffled air inlets and outlets that allow for airflow while minimizing sound transmission. Access doors and panels are meticulously sealed to prevent sound leakage, and vibration isolation mounts are frequently used to decouple the generator set from the enclosure structure, further reducing noise radiation. Some advanced enclosures also incorporate active noise cancellation systems, which use microphones and speakers to generate anti-noise waves that cancel out the generator's noise. While these advanced options come at a higher cost, they are invaluable in noise-sensitive environments such as residential areas, hospitals, or locations with stringent noise regulations. Choosing the right level of sound attenuation depends on a thorough assessment of the noise level requirements and the surrounding environment.

Key Features and Considerations for Effective Enclosures

Selecting the right noise reduction enclosure for a 500kVA industrial generator set involves careful consideration of several key features and design elements. Beyond just sound attenuation, an effective enclosure must also address practical operational needs. Ventilation is paramount. Generators generate significant heat, and inadequate ventilation can lead to overheating and performance issues. Enclosures must be designed with properly sized and strategically placed air inlets and outlets to ensure sufficient airflow for cooling, while still maintaining noise reduction performance. Accessibility for maintenance is another critical factor. Regular servicing and repairs are essential for generator longevity. Enclosures should incorporate easily accessible doors and panels that allow technicians to perform maintenance tasks without undue difficulty or the need to dismantle large portions of the enclosure. Cable entry points must be thoughtfully designed to accommodate power and control cables while maintaining the enclosure's acoustic integrity. Sealed and properly sized entry points are crucial to prevent sound leakage. Safety features are also paramount. Enclosures should be constructed from fire-resistant materials and may incorporate fire suppression systems. Proper grounding and electrical safety considerations are also essential. Furthermore, the durability and material construction of the enclosure are important, especially for outdoor installations. The enclosure must withstand weather conditions, corrosion, and potential physical impacts. Finally, the size and footprint of the enclosure should be considered, ensuring it fits within the available space and allows for adequate clearance around the generator set for maintenance and operation. A well-designed enclosure balances noise reduction performance with these practical operational and safety requirements.

Selecting the Right Enclosure for Your 500kVA Generator: A Step-by-Step Approach

Choosing the optimal noise reduction enclosure for your 500kVA industrial generator set is a process that requires a systematic approach. Firstly, assess your noise level requirements. Determine the acceptable noise levels at the boundaries of your property or in noise-sensitive areas nearby. Consult local noise regulations and consider the impact on workers and the surrounding community. Secondly, evaluate your operating environment. Will the generator be installed indoors or outdoors? What are the prevailing weather conditions? Are there any space constraints? Understanding the environment will help determine the necessary level of weather protection and the physical dimensions of the enclosure. Thirdly, consider the generator's specific characteristics. While we are focusing on 500kVA generators, different models may have slightly different noise profiles. Consult the generator manufacturer's specifications for noise level data. Fourthly, research available enclosure options. Explore different types of enclosures, compare their noise reduction ratings, features, and materials. Request detailed specifications and performance data from enclosure manufacturers. Fifthly, compare costs and benefits. Noise reduction enclosures represent an investment. Evaluate the cost of different options against the benefits they offer in terms of noise reduction, regulatory compliance, and improved operating conditions. Consider the long-term cost savings associated with reduced noise-related issues and improved worker productivity. Finally, consult with experts. Engage with generator and enclosure specialists who can provide guidance based on your specific needs and circumstances. They can help you assess your requirements, recommend suitable enclosure options, and ensure proper installation and integration. By following these steps, you can make an informed decision and select the noise reduction enclosure that best meets your needs for your 500kVA industrial generator set. Have you considered the long-term benefits of investing in a higher quality enclosure versus a cheaper, less effective option? It's a question worth pondering for sustained operational efficiency and compliance.

Our Company's Expertise in Noise Reduction Enclosures

At our company, we understand the critical importance of effective noise reduction for industrial generator sets. We specialize in providing high-quality, custom-engineered noise reduction enclosure solutions tailored to meet the specific needs of our clients, including those operating 500kVA generator sets. Our expertise lies in designing and manufacturing enclosures that not only achieve significant noise attenuation but also ensure optimal generator performance, accessibility, and longevity. We offer a comprehensive range of enclosure options, from standard weatherproof enclosures to advanced super silent enclosures, utilizing a variety of materials and acoustic technologies. Our engineering team works closely with clients to assess their specific noise reduction requirements, environmental conditions, and operational needs. We take into account factors such as desired noise levels, ventilation requirements, maintenance access, and site-specific constraints. We utilize advanced acoustic modeling and simulation tools to optimize enclosure designs for maximum noise reduction while ensuring proper ventilation and thermal management. Our enclosures are constructed from robust, high-quality materials, ensuring durability and longevity in demanding industrial environments. We pay meticulous attention to detail in the manufacturing process, ensuring precise fit and finish, and rigorous quality control. We also offer installation and commissioning services, ensuring seamless integration of the noise reduction enclosure with your 500kVA generator set. Our commitment is to provide our clients with reliable, high-performance noise reduction solutions that not only meet regulatory requirements but also create a more comfortable and productive working environment. We believe that investing in a quality noise reduction enclosure is an investment in operational efficiency, regulatory compliance, and long-term sustainability.

Practical Applications and Benefits of Noise Reduction Enclosures

The practical applications of noise reduction enclosures for 500kVA industrial generator sets are diverse and span across numerous industries. In manufacturing facilities located near residential areas, noise enclosures are essential for maintaining good community relations and complying with noise ordinances. Hospitals and healthcare facilities rely on backup generators, but noise must be minimized to ensure a peaceful healing environment for patients. Data centers, critical infrastructure hubs that often operate generators continuously for backup power, require quiet operation to protect sensitive equipment and maintain a comfortable working environment. Construction sites in urban areas often utilize generators, and noise enclosures help mitigate disturbance to surrounding neighborhoods. Telecommunication sites, frequently located in both urban and rural settings, benefit from noise enclosures to minimize environmental impact and ensure quiet operation. Event venues and outdoor entertainment spaces using generators for power can significantly improve the guest experience by reducing noise pollution. The benefits of implementing noise reduction enclosures are equally wide-ranging. Beyond regulatory compliance and reduced noise pollution, enclosures contribute to a safer and more comfortable working environment for personnel operating and maintaining the generator sets. They can also enhance generator performance and lifespan by providing protection from the elements and maintaining a more stable operating temperature. Moreover, investing in noise reduction demonstrates a commitment to environmental responsibility and good corporate citizenship, enhancing a company's reputation and public image. In essence, noise reduction enclosures are not just an expense; they are a strategic investment that yields tangible benefits across various aspects of industrial and commercial operations. It's about creating a better environment for everyone involved – employees, neighbors, and the broader community.

Conclusion: Investing in Quieter Operations with 500kVA Generator Enclosures

In conclusion, addressing noise pollution from 500kVA industrial generator sets is not just a desirable goal, but often a necessity for regulatory compliance, operational efficiency, and community harmony. Noise reduction enclosures offer a proven and effective solution for mitigating generator noise, transforming potentially disruptive machines into quieter, more environmentally responsible power sources. From basic weatherproof enclosures to advanced super silent designs, there is a wide range of options available to suit diverse needs and budgets. Selecting the right enclosure involves careful consideration of factors such as noise level requirements, operating environment, generator specifications, and practical operational needs. By understanding the sources of generator noise, the types of enclosures available, and the key features to consider, organizations can make informed decisions and invest in solutions that deliver significant and lasting benefits. Our company is dedicated to providing expert guidance and high-quality noise reduction enclosure solutions for 500kVA industrial generator sets. We are committed to helping our clients achieve quieter, more compliant, and more sustainable operations. Investing in noise reduction enclosures is an investment in a better working environment, improved community relations, and a more responsible operational footprint. It's a proactive step towards a quieter and more harmonious industrial landscape. We encourage you to explore the various options available and consider how noise reduction enclosures can enhance your operations and contribute to a more positive impact on your surroundings.

For more detailed information, please visit our official website: 500kVA generator enclosure

`