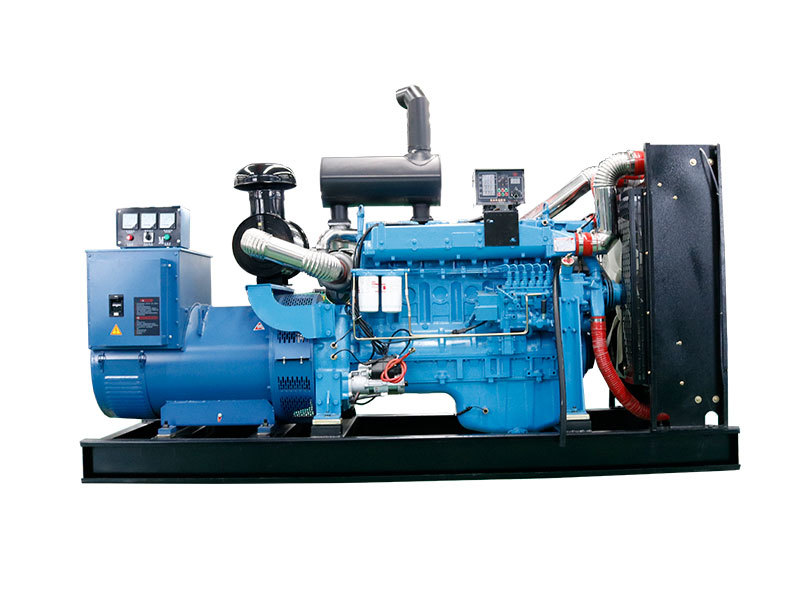

In today's world, where uninterrupted power supply is not just a convenience but often a necessity for businesses, homes, and critical infrastructure, generator sets stand as indispensable backup power sources. Whether it's a sudden grid outage, planned maintenance, or off-grid operations, understanding the comprehensive instructions for generator set operation and maintenance procedures is paramount. A generator set, often referred to as a genset, is a complex system comprising an engine and an alternator, working in tandem to convert mechanical energy into electrical energy. To ensure these systems perform reliably when needed most, and to maximize their operational lifespan, a thorough understanding of both operation and maintenance is crucial. This article aims to provide a detailed guide, covering essential aspects from initial start-up to long-term upkeep, empowering users to confidently manage their generator sets.

Understanding Generator Set Operation: A Step-by-Step Guide

Operating a generator set might seem straightforward, but a series of pre-start checks and careful procedures are essential to avoid damage and ensure safe operation. Before even thinking about turning the key or pressing the start button, a comprehensive pre-operation checklist should be diligently followed. This begins with a visual inspection of the entire unit. Are there any obvious leaks – fuel, oil, or coolant? Check fluid levels: engine oil, coolant, and fuel. Ensure the battery terminals are clean and securely connected. Inspect the air intake and exhaust systems for any obstructions. For fuel, especially in diesel generators, check for water contamination in the fuel tank, as water can severely damage the fuel injection system. Furthermore, verify that the generator is placed in a well-ventilated area, free from flammable materials, and that the exhaust fumes are safely directed away from occupied spaces. Ignoring these preliminary steps can lead to operational failures, safety hazards, and costly repairs down the line. It's not just about getting the generator running; it's about ensuring it runs safely and efficiently.

Starting and Running Your Generator Set

Once the pre-operation checks are complete, the actual starting procedure can commence. Most generator sets come with both manual and automatic start options. For manual start, typically, you'll need to turn the ignition key to the 'start' position and hold it until the engine cranks and starts. Release the key immediately once the engine fires up. Avoid prolonged cranking, as this can overheat the starter motor and drain the battery. For automatic start systems, which are common in standby generator applications, the system detects a mains power failure and initiates the starting sequence automatically. After starting, allow the generator to run at no-load for a few minutes. This warm-up period allows the engine oil to circulate properly and reach optimal operating temperature. During operation, continuously monitor the generator's gauges – voltage, current, frequency, oil pressure, and engine temperature. Any abnormal readings should be investigated immediately. Listen for unusual noises or vibrations, which could indicate a problem. Regularly check the exhaust for excessive smoke, which could signal issues with combustion or fuel mixture. Effective operation is not just about starting the generator; it's about constant monitoring and vigilance throughout its runtime.

Essential Generator Set Maintenance Procedures

Maintenance is the backbone of generator set longevity and reliability. Think of it like vehicle maintenance – regular servicing is crucial to prevent breakdowns and extend the lifespan of your car. Similarly, a generator set requires a structured maintenance schedule to keep it in peak condition. Maintenance can be broadly categorized into preventive and corrective. Preventive maintenance, done regularly, aims to preempt potential problems, while corrective maintenance addresses issues that have already arisen. A well-defined maintenance schedule should include daily, weekly, monthly, semi-annual, and annual tasks. Daily checks are simple visual inspections, while more in-depth tasks like filter replacements and system overhauls are part of the annual maintenance. Ignoring maintenance is a false economy. While it might seem like saving time and resources in the short term, it invariably leads to more significant problems, higher repair costs, and potential downtime in the long run. To be honest, a proactive maintenance approach is always more cost-effective and ensures peace of mind when you need your generator most.

Daily, Weekly, and Monthly Maintenance Tasks

Let's delve into the specifics of routine maintenance. Daily checks are quick and easy, focusing on visual inspection and basic fluid level checks. Check engine oil, coolant, and fuel levels before each operation or at the start of each day for standby units. Inspect for any leaks around the generator set. Ensure the area around the generator is clean and free of debris. Weekly maintenance expands on this, including starting the generator and letting it run for a short period, even if it's not needed for load. This helps keep the internal components lubricated and the battery charged. Check the battery voltage and ensure connections are tight and corrosion-free. Monthly maintenance includes all weekly tasks plus more detailed inspections. Check air filters and clean or replace them as needed. Inspect fuel filters and water separators, draining any accumulated water. Examine belts and hoses for wear and tear, replacing them if necessary. Run the generator under load for a period to verify its performance and stability. These routine tasks, though seemingly small, collectively ensure the generator's readiness and prevent minor issues from escalating into major failures. It's worth noting that consistent monthly maintenance can dramatically reduce the likelihood of unexpected breakdowns.

Semi-Annual and Annual Maintenance: In-Depth Checks

Semi-annual and annual maintenance procedures are more comprehensive and often require specialized tools and expertise. Semi-annually, tasks include changing the engine oil and oil filter. Coolant should be tested for freeze protection and corrosion inhibitors, and replaced if necessary. Inspect and clean the radiator externally and internally if needed. Check the condition of the exhaust system for leaks or corrosion. Inspect and test the automatic transfer switch (ATS) if one is installed, ensuring it functions correctly during simulated power outages. Annual maintenance is the most thorough service. It typically includes everything in the semi-annual schedule, plus fuel filter replacement, air filter replacement (if not done more frequently), spark plug replacement (for gasoline generators), valve adjustments, and injector cleaning (for diesel generators). The alternator should be inspected and cleaned, and insulation resistance tested. The control panel and wiring should be thoroughly checked for any signs of damage or deterioration. For larger generator sets, a load bank test is often recommended annually to simulate full load conditions and verify the generator's capacity and performance under stress. Frankly speaking, annual maintenance is best performed by qualified technicians to ensure all critical components are properly inspected and serviced.

Troubleshooting Common Generator Set Problems

Even with diligent maintenance, generator sets can sometimes encounter problems. Knowing how to troubleshoot common issues can save time and prevent minor problems from becoming major headaches. One of the most frequent issues is starting problems. If the generator fails to start, the first things to check are the battery and fuel supply. Ensure the battery is charged and terminals are clean. Verify that there is sufficient fuel in the tank and that the fuel shut-off valve is open. If the engine cranks but doesn't start, check for air in the fuel lines (especially in diesel systems) and inspect the spark plugs (in gasoline engines). Another common issue is low power output. This could be due to overloaded circuits, a faulty voltage regulator, or problems with the alternator. Check the load on the generator and ensure it's within the generator's rated capacity. Inspect wiring connections for looseness or corrosion. Overheating is another potential problem, often caused by insufficient coolant, a faulty thermostat, or a clogged radiator. Check coolant levels and inspect the radiator for obstructions. If you notice excessive exhaust smoke, it could indicate various issues. Black smoke often suggests rich fuel mixture or overloading, blue smoke indicates burning oil, and white smoke could be steam from coolant leakage or unburnt fuel. For complex issues, it's always best to consult the generator's service manual or contact a qualified technician. Remember, safety first – always disconnect the generator from the load and shut it down before attempting any troubleshooting or repairs.

Optimizing Generator Set Performance and Longevity

Beyond operation and maintenance, several factors can contribute to optimizing generator set performance and extending its lifespan. Proper sizing of the generator to the load is crucial. An undersized generator will be constantly overloaded, leading to premature wear and potential failure. An oversized generator, while not as detrimental, can operate inefficiently at light loads. Consider future power needs when selecting a generator. Regular testing under load is beneficial, particularly for standby generators. This not only verifies the generator's readiness but also helps burn off any accumulated carbon deposits in the engine. Fuel quality is also a significant factor, especially for diesel generators. Use clean, high-quality fuel and store it properly to prevent contamination and degradation. Fuel stabilizers can be added to fuel stored for extended periods. Pay attention to the operating environment. Protect the generator from extreme weather conditions, dust, and moisture. A dedicated generator enclosure can provide protection and reduce noise levels. Finally, keeping detailed records of operation, maintenance, and any repairs is invaluable. This history helps track performance, identify trends, and plan for future maintenance needs. In my experience, meticulous record-keeping often highlights potential issues before they become critical.

Choosing the Right Generator Set and Professional Support

Selecting the right generator set for your specific needs is the first critical step towards ensuring reliable backup power. Consider factors like power requirements, fuel type (diesel, gasoline, natural gas), application (standby, prime, portable), and environmental conditions. Our company offers a wide range of generator sets designed to meet diverse needs, from residential backup power to large-scale industrial applications. We understand that choosing the right generator and maintaining it effectively can be complex. That's why we not only provide high-quality generator sets but also comprehensive support services. Our expert team can assist you in selecting the ideal generator for your requirements, provide professional installation services, and offer ongoing maintenance contracts to keep your generator in top condition. We also provide training programs to empower your personnel with the knowledge and skills needed for routine operation and maintenance tasks. Have you ever wondered how to ensure your business or home is never without power? The answer lies in a reliable generator set and a partnership with a company dedicated to providing comprehensive power solutions. We are committed to ensuring your peace of mind through dependable products and expert support.

In conclusion, mastering comprehensive instructions for generator set operation and maintenance procedures is not just about following steps; it's about understanding the underlying principles and adopting a proactive approach. From meticulous pre-operation checks and diligent routine maintenance to effective troubleshooting and performance optimization, each aspect contributes to the overall reliability and longevity of your generator set. By adhering to these guidelines, you can ensure that your generator set is always ready to provide dependable power when you need it most. Remember, a well-maintained generator is a reliable generator, offering peace of mind and safeguarding your operations from power disruptions. For more detailed information, please visit our official website: generator set operation