Ensuring a consistent and reliable power supply is paramount for countless operations, from critical infrastructure and healthcare facilities to manufacturing plants and even residential buildings. When grid power fails, or when power is simply unavailable, generator sets step in as the backbone of energy continuity. However, selecting the right generator isn't just about having backup power; it's about having the right amount of power. Incorrectly sized generator sets can lead to a host of problems, ranging from inefficient fuel consumption and premature wear and tear to, more critically, system failures when you need power most. Therefore, understanding generator set sizing and how to accurately determine the right power output is not just a technical detail—it's a fundamental aspect of reliable power management. This article will guide you through the essential steps and considerations to ensure you choose a generator set that perfectly matches your power requirements, providing peace of mind and operational efficiency.

Understanding Your Power Needs: The First Crucial Step

Before diving into calculations and technical specifications, the very first step in generator set sizing is to thoroughly understand your power needs. This isn't as simple as just looking at your current electricity bill. It requires a detailed analysis of all the electrical devices and systems you intend to power with the generator. Start by creating a comprehensive inventory of every piece of equipment that will be connected to the generator. This list should include everything from essential lighting and HVAC systems to critical machinery, computers, and any specialized equipment. For each item on your list, note down its power rating, typically measured in watts (W) or kilowatts (kW). It's also important to distinguish between continuous power requirements and any surge or starting power demands. Many devices, especially those with motors like air conditioners or pumps, require significantly more power to start up than they do to run continuously. Failing to account for these starting surges is one of the most common mistakes in generator sizing and can lead to generator overload and system failure. Accurate power assessment lays the foundation for selecting a generator set that is neither underpowered, leaving you in the dark, nor overpowered, leading to unnecessary expense and inefficiency.

Calculating Total Power Demand: Beyond Simple Addition

Once you have meticulously inventoried your electrical equipment and their respective power ratings, the next step is to calculate the total power demand. However, simply adding up the wattage of all devices is not enough. This is because not all devices will be running simultaneously, and as mentioned before, starting surges can significantly increase the instantaneous power demand. To get a more realistic picture, you need to consider both the running wattage and the starting wattage for each device, especially those with motors. For devices with motors, the starting wattage can be two to three times, or even more, than the running wattage. Manufacturers usually provide both ratings. If only the running wattage is available, you might need to estimate the starting wattage based on the type of motor. After noting down both running and starting wattages, you need to determine which devices are likely to be running concurrently. It’s rare that every single appliance or piece of equipment in a facility will operate at the exact same moment. Analyze your operational patterns to identify the maximum anticipated simultaneous load. For example, in an office setting, lights, computers, and HVAC systems might run concurrently during business hours, but heavy machinery may only operate intermittently. By carefully considering these factors, you can arrive at a more accurate estimate of your peak power demand, which is crucial for correct generator sizing.

Understanding Different Load Types: Resistive, Inductive, and Capacitive

Delving deeper into power calculations, it's important to understand the different types of electrical loads: resistive, inductive, and capacitive. Resistive loads, such as incandescent lights, heaters, and toasters, are the simplest. Their power demand is relatively stable and predictable. Inductive loads, on the other hand, like motors, transformers, and fluorescent lights, are more complex. They require a significant surge of power when starting due to the magnetic fields they generate. This starting surge, often referred to as inrush current, is what necessitates considering starting wattage. Capacitive loads, less common in typical applications but present in electronics and some lighting systems, can also cause current surges, though generally less dramatic than inductive loads. Generators need to be sized to handle the starting surges of inductive loads. Ignoring this aspect can lead to voltage dips, frequency fluctuations, and potential damage to both the generator and the connected equipment. Many generator manufacturers provide guidance on handling inductive loads, often specifying a "motor starting kVA" or similar rating. Understanding the composition of your load—the proportion of resistive, inductive, and capacitive loads—will refine your sizing calculations and ensure the generator can handle the dynamic nature of your power demands effectively.

Power Factor and Generator Efficiency: Hidden Considerations

Beyond wattage and load types, two often overlooked factors in generator set sizing are power factor and generator efficiency. Power factor is the ratio of real power (kW) to apparent power (kVA). Ideal power factor is 1, but in reality, especially with inductive loads, it's often less. A lower power factor means that while your equipment might consume a certain amount of real power (kW), the generator needs to supply more apparent power (kVA) to deliver that real power. Generators are typically rated in kVA, and understanding the power factor of your load is crucial to avoid undersizing. For instance, if your calculated real power demand is 100 kW, and your average power factor is 0.8, you'll need a generator with a kVA rating of at least 100 kW / 0.8 = 125 kVA. Ignoring power factor can lead to the generator being overloaded even if the kW rating seems sufficient. Generator efficiency also plays a role. No generator operates at 100% efficiency. Some energy is always lost as heat and noise. Efficiency varies depending on the generator's load level; generators are generally most efficient when running at around 75-80% of their rated capacity. Running a significantly oversized generator at a very low load will be inefficient, wasting fuel and potentially leading to engine problems. Conversely, consistently running a generator at or near its maximum capacity can shorten its lifespan and increase the risk of breakdowns. Considering both power factor and generator efficiency ensures not only reliable power but also cost-effective and sustainable operation.

Environmental Factors and Derating: Altitude and Temperature Effects

The environment in which a generator set operates can significantly impact its performance and power output. Two primary environmental factors to consider are altitude and ambient temperature. Altitude affects engine performance because as altitude increases, air density decreases. Less dense air means less oxygen available for combustion, which directly reduces the engine's power output. Generator manufacturers typically provide derating factors for altitude. For example, a generator might be derated by 3-4% for every 1000 feet above sea level. If your generator is to be installed at a high altitude location, you must factor in this derating when sizing the unit. Ignoring altitude derating can result in a generator that is unable to meet the required power demand at its operating location, even if it was correctly sized for sea-level conditions. Ambient temperature also affects generator performance, particularly for diesel generators. Higher temperatures can reduce engine efficiency and cooling capacity. While modern generators are designed to operate within a wide temperature range, extreme temperatures, especially high temperatures, can necessitate derating. Manufacturers often specify derating factors for high ambient temperatures as well. Furthermore, extreme cold can also pose challenges, particularly with starting diesel engines. In cold climates, features like engine preheaters and cold-weather lubricants might be necessary. Considering both altitude and temperature derating ensures that the generator will deliver its rated power output reliably under the specific environmental conditions of its installation site. It’s always best to consult with a generator specialist to accurately assess these environmental factors and apply appropriate derating.

Future-Proofing Your Generator Sizing: Planning for Growth

While accurately assessing current power needs is crucial, forward-thinking generator sizing also involves anticipating future power requirements. Businesses and households alike often expand their operations or increase their electrical equipment over time. Installing a generator set that precisely matches today's needs might leave you undersized in just a few years. Therefore, it’s prudent to consider potential future growth when determining generator size. Think about any planned expansions, additions of new equipment, or increased electrical loads you foresee in the next 5-10 years. Oversizing slightly for future needs can be a wise investment. A commonly recommended practice is to add a buffer of around 20-25% to your calculated power demand to accommodate future growth and unexpected surges. However, it’s also important to avoid excessive oversizing. As mentioned earlier, generators operate most efficiently at around 75-80% load. Grossly oversizing can lead to inefficient operation, increased fuel consumption, and higher initial costs without corresponding benefits. The key is to strike a balance – size the generator to meet current needs comfortably while providing enough headroom for reasonable future expansion. This future-proofing approach ensures that your generator set remains a reliable power solution for years to come, avoiding costly upgrades or replacements down the line. Careful planning for future needs is a hallmark of smart generator set sizing.

Common Mistakes to Avoid in Generator Set Sizing

Despite the seemingly straightforward process, many common mistakes can lead to incorrect generator set sizing, resulting in operational problems and inefficiencies. One of the most prevalent errors is underestimating starting wattage, especially for inductive loads like motors and compressors. Simply adding running wattages without considering the significantly higher starting demands can lead to generator overload and tripping. Another frequent mistake is ignoring power factor. Focusing solely on kW ratings and neglecting kVA can result in insufficient apparent power capacity, particularly in industrial settings with substantial inductive loads. Overlooking environmental factors like altitude and temperature is another pitfall. Failing to derate for high altitude or extreme temperatures can lead to underperformance in actual operating conditions. Conversely, grossly oversizing the generator is also a mistake. While future-proofing is important, excessive oversizing leads to inefficient operation, higher fuel consumption, and increased initial investment. Generators run most efficiently at moderate loads, and significantly underloaded generators can be less reliable and more costly to operate in the long run. Finally, not consulting with experts is a common oversight. Generator sizing can be complex, and professional guidance from experienced power systems engineers or generator specialists can prevent costly errors and ensure optimal selection. Avoiding these common mistakes through careful planning and expert consultation is crucial for successful generator set sizing and reliable power backup.

The Benefits of Correct Generator Set Sizing: Efficiency, Reliability, and Longevity

Investing the time and effort in accurate generator set sizing yields significant benefits that extend far beyond simply having backup power. Efficiency is a primary advantage. A correctly sized generator operates closer to its optimal load range, maximizing fuel efficiency and reducing operating costs over time. This translates directly to lower fuel bills and a reduced carbon footprint. Reliability is another key benefit. A properly sized generator is less likely to be overloaded or stressed, leading to fewer breakdowns and a more dependable power supply when you need it most. This reliability is critical for businesses, healthcare facilities, and any operation where power continuity is essential. Longevity of the generator itself is also enhanced by correct sizing. Operating within its designed capacity reduces wear and tear on engine components and electrical systems, extending the generator's lifespan and postponing costly replacements. Moreover, correct sizing ensures protection of connected equipment. Voltage sags and frequency fluctuations caused by an undersized generator can damage sensitive electronic devices. A properly sized generator provides stable and clean power, safeguarding your valuable equipment. In essence, accurate generator set sizing is not just about avoiding problems; it's about optimizing performance, ensuring reliability, maximizing lifespan, and achieving long-term cost savings. It’s an investment in operational efficiency and peace of mind.

How Our Products and Services Can Help You

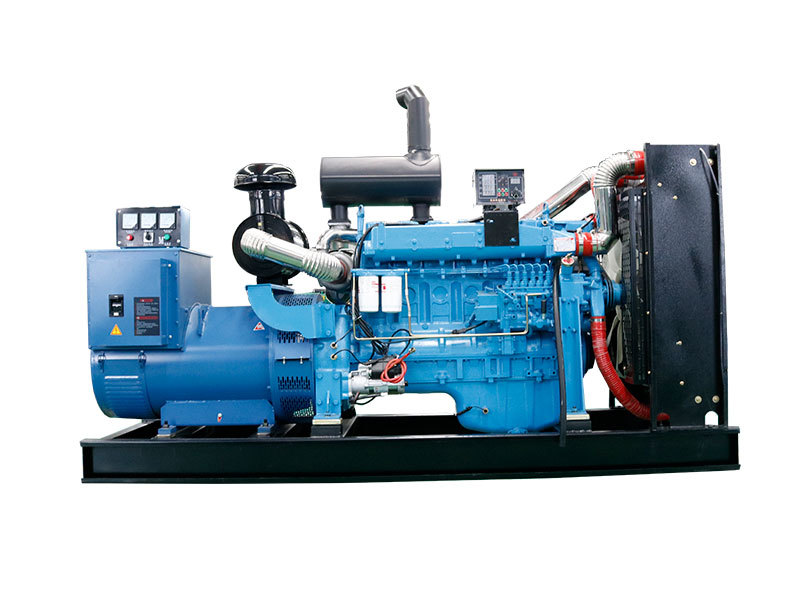

At our company, we understand the complexities of generator set sizing and are dedicated to providing solutions that ensure you get the right power output for your specific needs. We offer a comprehensive range of generator sets, from portable units to large industrial-grade systems, and our experienced team can guide you through every step of the sizing process. We begin with a thorough assessment of your power requirements, taking into account all load types, starting surges, power factor, and environmental conditions. Our experts utilize advanced sizing tools and industry best practices to calculate your optimal generator size accurately. We also consider future growth potential, ensuring your generator set remains adequate for your evolving needs. Beyond sizing, we offer complete installation, maintenance, and support services, providing a turnkey solution for your power backup requirements. Our generators are built to the highest quality standards, ensuring reliability, efficiency, and longevity. Whether you need backup power for a small business, a large industrial facility, or a critical infrastructure application, we have the expertise and product range to meet your demands. We are committed to helping you navigate the complexities of generator selection and sizing, providing peace of mind and reliable power solutions you can depend on. Let us partner with you to ensure your power needs are met effectively and efficiently.

For more detailed information, please visit our official website: generator set sizing