In an increasingly interconnected world, the demand for reliable power extends to the most remote and challenging corners of the globe. From the blistering heat of desert operations to the frigid expanses of arctic research stations, extreme environments present unique obstacles to consistent power generation. Selecting the right generator set for these conditions isn't just a matter of picking a standard model; it requires a deep understanding of environmental factors and specialized configuration solutions. The consequences of generator failure in such locations can range from operational disruptions to critical safety hazards, making informed selection and bespoke engineering paramount. This article delves into the critical considerations for choosing generator sets designed to thrive in extreme environments, highlighting the specialized configurations necessary for dependable performance from desert heat to arctic cold.

Understanding the Challenges of Extreme Environments

Extreme environments, whether characterized by scorching temperatures, bone-chilling cold, high altitude, or corrosive atmospheres, impose significant stress on generator sets. The most obvious challenge is temperature. In desert environments, ambient temperatures can soar to well over 50°C (122°F), pushing engine cooling systems to their limits and potentially leading to overheating and component failure. Conversely, arctic conditions can plunge to -40°C (-40°F) or even lower, causing lubricants to thicken, batteries to lose efficiency, and starting systems to struggle. Dust and sand, prevalent in deserts, can infiltrate engine components, causing abrasion and clogging filters, while ice and snow in arctic regions can obstruct air intakes and damage sensitive parts. Altitude also plays a role, as thinner air reduces engine power output and impacts combustion efficiency. Each extreme environment presents a unique cocktail of challenges that necessitate tailored generator set configurations.

Desert Environments: Heat, Dust, and Sand

Desert environments present a formidable trio of challenges: intense heat, pervasive dust, and abrasive sand. The relentless sun and high ambient temperatures demand robust cooling systems capable of dissipating heat effectively. Standard cooling systems often prove inadequate, necessitating upgrades such as larger radiators, enhanced fans, and specialized coolants designed for high-temperature operation. Dust and sand ingress is another major concern. Fine particles can penetrate engine compartments, leading to premature wear of moving parts and clogging air and fuel filters. To combat this, specialized air filtration systems with multiple stages of filtration, including cyclone separators and high-efficiency filters, are crucial. Furthermore, enclosures must be designed to be dust-tight, protecting sensitive components from contamination. Materials selection also becomes critical; components must withstand the harsh UV radiation and abrasive nature of sand without degrading or failing prematurely. In desert applications, a generator set's resilience to heat and dust is not merely desirable—it is essential for sustained operation.

Arctic Environments: Extreme Cold and Ice

The arctic presents a contrasting but equally demanding set of challenges centered around extreme cold and the presence of ice and snow. Sub-zero temperatures drastically affect engine performance and reliability. Engine oil and fuel can thicken or even gel, hindering lubrication and fuel flow. Batteries lose significant capacity at low temperatures, making cold starting a major hurdle. Metal components can become brittle and prone to cracking under stress. Specialized configurations for arctic environments address these issues head-on. Engine preheaters are essential to ensure reliable starting, warming the engine block and oil to a temperature where combustion can initiate effectively. Low-temperature lubricants and fuels are necessary to maintain proper viscosity and prevent gelling. Battery blankets and heating systems can maintain battery temperature and ensure sufficient starting power. Enclosures must be designed to withstand heavy snow loads and prevent ice buildup, which could obstruct air intakes or damage components. Arctic-ready generator sets are engineered to not just survive but thrive in conditions that would cripple standard equipment.

Specialized Configuration Solutions for Generator Sets

Addressing the challenges of extreme environments requires moving beyond standard generator set designs and implementing specialized configuration solutions. These modifications touch upon every critical system of the generator set, from the engine and alternator to the control panel and fuel system. The goal is to fortify the generator set against the specific stresses of its operating environment, ensuring reliable performance and extended service life. This customization process often involves selecting specific components, modifying existing systems, and implementing additional protective measures tailored to the anticipated conditions. For instance, a generator destined for a high-altitude desert environment would necessitate a different suite of modifications compared to one intended for a low-altitude arctic application. The key lies in a thorough assessment of the environmental demands and a strategic application of specialized configurations.

Engine Modifications for Temperature Extremes

Engine modifications are at the heart of specialized configurations for extreme temperatures. In hot environments, enhanced cooling systems are paramount. This can involve installing larger radiators with increased surface area, employing more powerful cooling fans, and utilizing specialized high-temperature coolants that maintain their properties at elevated temperatures. Oil coolers may also be upgraded to ensure optimal oil viscosity and lubrication even under extreme heat. Conversely, in cold environments, engine preheaters are indispensable for reliable starting. These preheaters warm the engine block, oil, and coolant, reducing viscosity and facilitating easier cranking. Thermostatically controlled coolant heaters and oil pan heaters are common solutions. Furthermore, fuel heaters may be required to prevent fuel waxing or gelling in extremely cold conditions. Engine control units (ECUs) may also be recalibrated to optimize performance and emissions in extreme temperature ranges, ensuring efficient operation regardless of ambient conditions. These engine-focused modifications are critical for ensuring the generator set can start and operate reliably in the face of temperature extremes.

Alternator and Electrical System Protection

The alternator and electrical system of a generator set also require specialized protection in extreme environments. In dusty and sandy conditions, alternators need to be protected from particle ingress, which can lead to insulation breakdown and reduced efficiency. Enclosed and fan-cooled (TEFC) alternators or those with enhanced sealing are often preferred. Additionally, applying conformal coatings to windings can provide an extra layer of protection against dust and moisture. In humid environments, condensation can be a major issue, leading to corrosion and electrical faults. Anti-condensation heaters within the alternator enclosure can maintain a slightly elevated temperature, preventing moisture buildup. For arctic environments, components must be selected for their ability to withstand extreme cold without becoming brittle or failing. Low-temperature rated wiring and connectors are essential, as standard materials can become inflexible and prone to cracking at sub-zero temperatures. Control panels and electrical enclosures must be weatherproof and, in some cases, insulated and heated to ensure reliable operation of sensitive electronics. Protecting the electrical heart of the generator set is crucial for maintaining consistent power output and preventing costly downtime.

Fuel System and Enclosure Considerations

The fuel system and enclosure of a generator set are often overlooked but play a vital role in its performance in extreme environments. In hot desert conditions, fuel can vaporize in fuel lines, leading to vapor lock and fuel starvation. Fuel coolers and pressurized fuel systems can mitigate this issue. Fuel tanks may also require shading or insulation to reduce heat absorption. In arctic environments, fuel gelling is a significant concern. Using winter-grade diesel fuel with a lower cloud point is essential, and fuel heaters may be necessary to maintain fuel flow. Fuel tanks might also need insulation to prevent excessive cooling. The enclosure itself must be robust enough to withstand the environmental stresses. Desert enclosures need to be dust-tight and offer excellent ventilation to dissipate heat. Arctic enclosures must be heavily insulated to retain heat and protect against snow and ice loads. Materials used for enclosures should be chosen for their resistance to UV radiation, corrosion, and extreme temperatures. Properly designed fuel systems and enclosures are integral to ensuring the long-term reliability and efficient operation of generator sets in extreme environments.

Practical Applications and Our Expertise

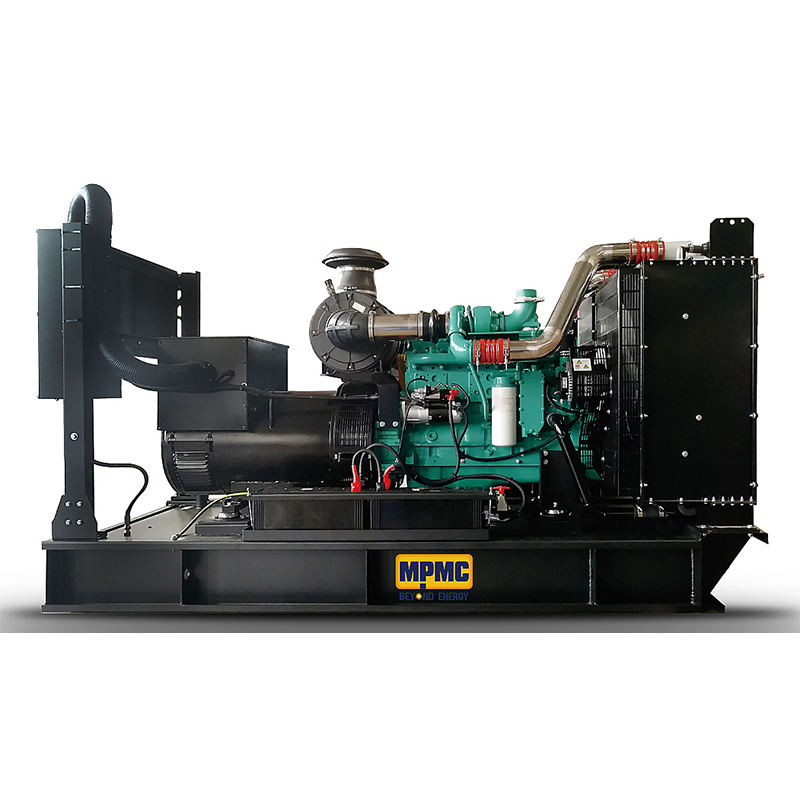

The need for specialized generator sets in extreme environments spans a wide range of critical applications. Remote mining operations in deserts or high-altitude regions rely heavily on dependable power for extraction, processing, and worker accommodations. Scientific research stations in the arctic and Antarctic require continuous power for experiments, life support systems, and communication. Telecommunications infrastructure in remote areas, often exposed to harsh weather conditions, depends on generators to maintain network uptime. Disaster relief efforts in extreme climates demand robust and portable power solutions to support emergency services and affected populations. Our company understands these diverse needs and specializes in providing tailored generator set solutions for extreme environments. We leverage our engineering expertise and in-depth knowledge of environmental challenges to configure generator sets that meet the specific demands of each application. From custom cooling and heating systems to specialized filtration and protective enclosures, we ensure our generator sets deliver reliable power, no matter how extreme the conditions.

Have you ever considered the logistical complexity of maintaining power for a remote research outpost in Antarctica during the polar winter? Or the critical need for uninterrupted electricity at a desert mine site operating 24/7? These scenarios underscore the importance of meticulously planned and expertly configured generator sets. Our approach begins with a comprehensive assessment of the operational environment, taking into account temperature extremes, dust and humidity levels, altitude, and any other relevant factors. Based on this assessment, we engineer bespoke solutions, selecting the optimal engine, alternator, control system, and enclosure for the specific application. We rigorously test our generator sets under simulated extreme conditions to ensure they meet the highest standards of performance and reliability. By focusing on specialized configurations and robust engineering, we empower our clients to operate confidently and efficiently, even in the most challenging environments on Earth.

In conclusion, selecting a generator set for extreme environments is far from a one-size-fits-all proposition. It demands a nuanced understanding of the specific environmental challenges and the implementation of specialized configuration solutions. From desert heat to arctic cold, each extreme environment requires a tailored approach to ensure reliable power generation. By focusing on engine modifications, alternator protection, and robust fuel and enclosure systems, it's possible to engineer generator sets that not only survive but thrive in these demanding conditions. Our company is dedicated to providing these specialized solutions, drawing upon our expertise to deliver dependable power wherever it's needed, regardless of the environmental extremes. Choosing the right generator set is an investment in operational continuity and safety, particularly in environments where failure is simply not an option.

For more detailed information, please visit our official website: extreme environment generators