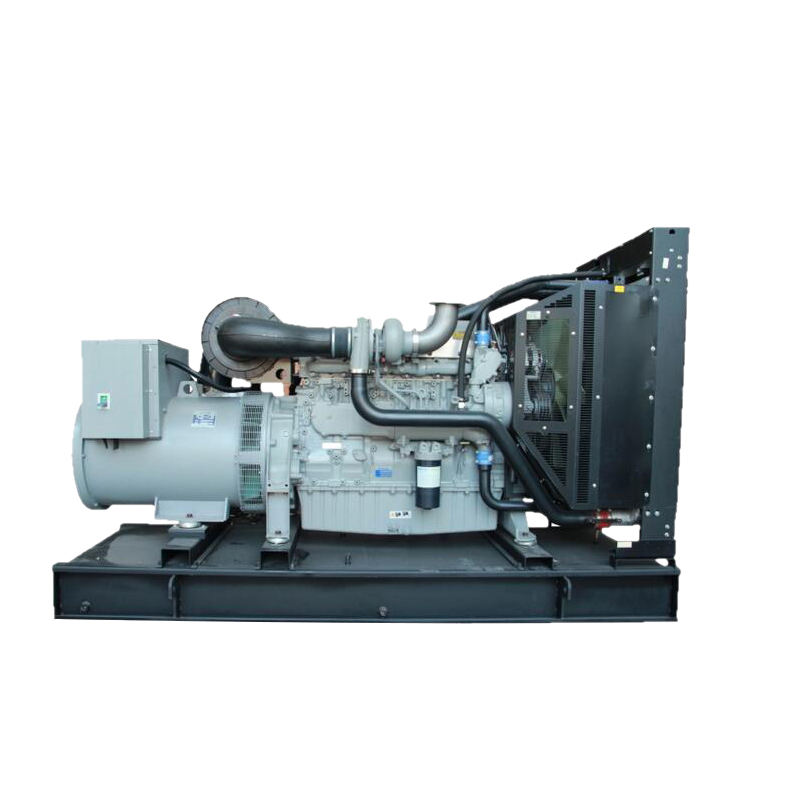

Critical backup power is no longer a luxury; it's a necessity. For businesses and organizations that rely on uninterrupted power, a 100kva generator set offers a robust solution. But simply purchasing a generator isn't enough. Proper installation is absolutely paramount to ensuring reliable performance when you need it most. Let's delve into the best practices for installing a 100kva generator set, covering everything from site preparation to final testing. Why is this meticulous approach so vital? Because the cost of downtime far outweighs the investment in a professional and thorough installation.

Site Selection and Preparation

The first step in installing a 100kva generator set is choosing the right location. This isn't as simple as finding an empty space. Consider factors like ventilation, noise levels, proximity to flammable materials, and accessibility for maintenance. Adequate ventilation is crucial for dissipating heat and preventing the buildup of harmful gases. Ideally, the generator should be housed in a well-ventilated enclosure or a dedicated room. Noise is another concern, especially in residential or densely populated areas. Sound attenuation measures, such as acoustic enclosures or barriers, may be necessary. Furthermore, ensure the site is level and capable of supporting the generator's weight, which can be considerable for a 100kva unit. A concrete pad is generally recommended to provide a stable and durable foundation. Don't underestimate the importance of future accessibility; you’ll need ample space for servicing and repairs. Poor planning at this stage can lead to significant headaches down the line. Have you considered all potential environmental impacts of your generator placement?

Electrical Connections and Wiring

The electrical connections are the heart of the generator's integration with your existing power system. This is definitely an area where you want to bring in certified electricians experienced with generator installations. Improper wiring can not only damage the generator but also pose a serious safety hazard. The transfer switch is a critical component, allowing you to seamlessly switch between utility power and generator power. It's worth noting that automatic transfer switches (ATS) are generally preferred for critical applications, as they provide instant power restoration in the event of an outage. Size your wiring appropriately to handle the generator's full output capacity. Undersized wiring can lead to voltage drops and overheating, potentially causing equipment failure. Remember to adhere to all local electrical codes and regulations. A qualified electrician will be familiar with these requirements and ensure that the installation meets all safety standards. Frankly speaking, skimping on the electrical connections is a recipe for disaster.

Fuel System Installation

A reliable fuel supply is essential for continuous generator operation. The type of fuel system – whether it's diesel, natural gas, or propane – will influence the installation process. Diesel generators typically require a fuel storage tank, which must be sized to provide sufficient runtime during extended power outages. Natural gas generators, on the other hand, require a connection to the natural gas pipeline. Propane generators can utilize either a propane tank or a connection to a propane supply line. Regardless of the fuel type, it's crucial to ensure that the fuel system is properly vented and protected from leaks. Fuel lines should be made of approved materials and installed according to manufacturer's specifications. Consider also the accessibility of the fuel supply for refueling or maintenance. Implementing a fuel monitoring system can also be a wise investment, allowing you to track fuel levels and anticipate refueling needs. We can assist with selecting the appropriate fuel system based on your requirements and provide expert installation services to guarantee safe and reliable operation.

Exhaust System Considerations

The exhaust system is responsible for safely venting exhaust gases away from the generator and the surrounding area. Improperly installed exhaust systems can lead to carbon monoxide buildup, which is a serious health hazard. Exhaust pipes should be made of durable, heat-resistant materials and properly insulated to prevent burns. The exhaust system should also be designed to minimize backpressure, which can reduce the generator's efficiency and power output. In my experience, paying close attention to the exhaust system design can significantly improve the overall performance and safety of the generator. Consider using a muffler to reduce noise levels and direct the exhaust gases away from occupied areas. It's also important to comply with all local environmental regulations regarding emissions. Many experts agree that regular inspections and maintenance of the exhaust system are essential to ensure its continued safe and efficient operation. Have you thought about the long-term maintenance requirements of your exhaust system?

Cooling System Setup

Generators generate a lot of heat, and a properly functioning cooling system is vital to prevent overheating and engine damage. 100kva generators typically use a radiator-based cooling system, which requires adequate airflow to dissipate heat. Ensure that the radiator is free from obstructions and that there is sufficient space around the generator for air to circulate. Liquid-cooled generators require a coolant supply and a system for circulating the coolant through the engine. Regularly check the coolant level and condition, and replace it as needed. Air-cooled generators, on the other hand, rely on forced air to cool the engine. Ensure that the air vents are not blocked and that the fan is operating properly. Overheating is a common cause of generator failure, so it's worth investing in a robust cooling system and implementing a regular maintenance schedule. Interestingly enough, some installations benefit from supplemental cooling, especially in hotter climates.

Testing and Commissioning

Once the generator is installed, it's crucial to thoroughly test and commission the system to ensure that it's operating correctly. This includes verifying all electrical connections, checking the fuel system for leaks, and testing the cooling system. Perform a load test to simulate a real-world power outage and verify that the generator can handle the expected load. The automatic transfer switch (ATS) should also be tested to ensure that it seamlessly switches between utility power and generator power. Document all test results and keep them on file for future reference. Commissioning should also include training for personnel who will be responsible for operating and maintaining the generator. This training should cover topics such as startup and shutdown procedures, troubleshooting common problems, and performing routine maintenance tasks. Remember that commissioning is not just a formality; it's an essential step in ensuring the reliable operation of your generator.

Regular Maintenance and Servicing

Even the best-installed generator requires regular maintenance to ensure its continued performance and longevity. Develop a comprehensive maintenance schedule that includes tasks such as oil changes, filter replacements, and inspections of all critical components. Regularly check the generator for any signs of wear and tear, and address any issues promptly. Keep a log of all maintenance activities, including dates, tasks performed, and parts replaced. It's worth considering a service agreement with a reputable generator service company to provide preventative maintenance and emergency repairs. This can help to minimize downtime and ensure that your generator is always ready when you need it. Remember, preventative maintenance is always more cost-effective than reactive repairs. Our company offers comprehensive maintenance and servicing packages to keep your 100kva generator set in top condition. Neglecting maintenance is a false economy; it will inevitably lead to more costly repairs and downtime in the long run.

Remote Monitoring and Control

In today's connected world, remote monitoring and control capabilities can provide valuable insights into your generator's performance. Remote monitoring systems can track parameters such as voltage, current, frequency, fuel level, and operating temperature. These systems can also send alerts via email or SMS if any issues are detected, allowing you to respond quickly and prevent potential problems. Remote control capabilities allow you to start and stop the generator remotely, as well as adjust settings such as voltage and frequency. This can be particularly useful for managing multiple generators or for responding to power outages from a remote location. Remote monitoring and control systems can also provide valuable data for optimizing generator performance and improving energy efficiency. These systems are becoming increasingly affordable and user-friendly, making them a worthwhile investment for many organizations. Are you leveraging technology to maximize the uptime of your backup power system?

In conclusion, achieving critical backup power with a 100kva generator set hinges on meticulous installation practices. From careful site selection and robust electrical connections to comprehensive testing and ongoing maintenance, every step is crucial. By adhering to these best practices, you can ensure a reliable and efficient power solution that safeguards your operations during critical times. We understand the importance of dependable backup power. Our company provides expert installation services and high-quality generator sets to meet your specific needs.

For more detailed information, please visit our official website: https://www.hsgeneratorset.com