When it comes to selecting a generator set for industrial applications, the choice between gas and diesel power can be a crucial one. Have you ever wondered which option truly reigns supreme in terms of performance, cost-effectiveness, and environmental responsibility? This comprehensive comparison delves into the intricacies of both gas and diesel generator sets, equipping you with the knowledge to make an informed decision tailored to your specific needs. From initial investment to long-term operational expenses, fuel efficiency, maintenance requirements, and environmental considerations, we'll explore the key factors that differentiate these two powerhouses.

Understanding the Fundamentals

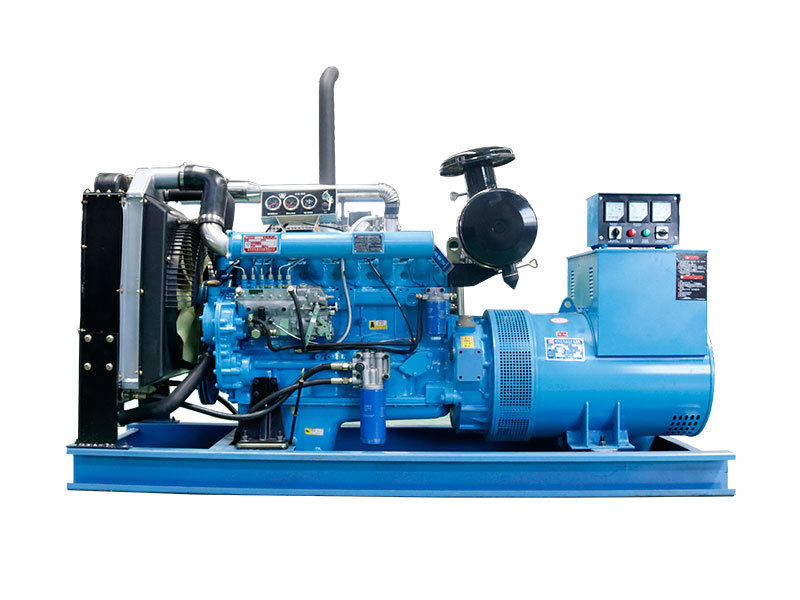

At their core, both gas and diesel generator sets perform the same function: converting mechanical energy into electrical energy. However, the process by which they achieve this differs significantly, leading to variations in their performance characteristics. Diesel generators typically utilize compression ignition, where air is compressed to a high temperature, and fuel is injected, causing combustion. This process generally results in higher thermal efficiency compared to gas engines. Gas generators, on the other hand, often employ spark ignition, similar to gasoline engines in cars. The fuel and air mixture is ignited by a spark plug. Understanding these fundamental differences is the first step in appreciating the trade-offs between the two technologies. In my experience, many businesses overlook these subtle differences and end up making a suboptimal choice. Considering the big picture, efficiency at every stage is the name of the game when it comes to industrial power solutions.

Cost Considerations: Initial Investment vs. Long-Term Expenses

The initial purchase price is often a primary consideration for industrial users. Generally, gas generator sets tend to have a lower upfront cost compared to their diesel counterparts. This can be attributed to simpler engine designs and lower manufacturing costs for gas-powered engines. However, it's crucial to look beyond the initial price tag. Long-term expenses, such as fuel costs, maintenance, and potential downtime, can significantly impact the total cost of ownership. Diesel fuel, while often more expensive per gallon than natural gas, provides better fuel efficiency, meaning you can generate more electricity per unit of fuel. Maintenance costs for diesel generators can sometimes be higher due to more complex components and stricter emissions regulations. It's a balancing act, and a thorough cost analysis, including projected fuel prices and maintenance schedules, is essential to make the most economically sound decision. In my experience, failing to account for lifetime costs can lead to significant budgetary issues down the line.

Fuel Efficiency and Availability

Fuel efficiency is a critical factor in determining the operational costs of generator sets. Diesel generators typically exhibit superior fuel efficiency compared to gas generators, especially under heavy loads. This means that for the same amount of electricity generated, a diesel generator will consume less fuel than a gas generator. This difference can be substantial, particularly in applications where the generator operates for extended periods. Fuel availability is another key consideration. Diesel fuel is widely available globally, making it a convenient choice in most locations. Natural gas, on the other hand, requires access to a natural gas pipeline or the availability of liquefied petroleum gas (LPG) or propane. The availability of natural gas infrastructure can vary significantly depending on the region. It’s worth noting that biogas, derived from anaerobic digestion, can be used to fuel specially designed gas generators, offering a renewable energy alternative. Are your operations located near a natural gas pipeline, or would you need to rely on fuel delivery? This is a critical question to address.

Maintenance Requirements and Reliability

Maintenance requirements and overall reliability are crucial for minimizing downtime and ensuring continuous power supply. Diesel generators are known for their robust construction and long lifespan, often requiring less frequent overhauls compared to gas generators. However, diesel engines can be more complex, requiring specialized knowledge for maintenance and repairs. Gas generators, while potentially having shorter lifespans, can be simpler to maintain, with readily available parts and service technicians. Regular maintenance, including oil changes, filter replacements, and system inspections, is essential for both types of generators to ensure optimal performance and longevity. Interestingly enough, advancements in technology are leading to more sophisticated monitoring systems that can predict potential failures and schedule maintenance proactively, regardless of the fuel type. Proper maintenance planning is an investment in reliability and avoids expensive repairs and downtime.

Environmental Impact and Emissions Regulations

Environmental concerns and stringent emissions regulations are increasingly influencing the choice of generator sets. Diesel generators have historically been associated with higher emissions of particulate matter (PM) and nitrogen oxides (NOx), which are harmful air pollutants. However, advancements in diesel engine technology, such as diesel particulate filters (DPFs) and selective catalytic reduction (SCR) systems, have significantly reduced emissions. Gas generators, particularly those fueled by natural gas, generally produce lower levels of PM and NOx compared to older diesel models. However, they can emit methane, a potent greenhouse gas. The overall environmental impact depends on the specific engine technology, fuel source, and emission control systems employed. Compliance with local, state, and federal emissions regulations is paramount, and choosing a generator that meets these requirements is essential for sustainable operations. Many experts agree that investing in cleaner technologies upfront can mitigate environmental risks and avoid costly penalties in the long run.

Noise Levels and Operational Considerations

Noise levels can be a significant consideration, especially in urban or noise-sensitive environments. Diesel generators tend to produce more noise than gas generators due to the combustion process and engine design. Noise reduction measures, such as enclosures and mufflers, can be implemented to mitigate noise pollution. Gas generators, with their smoother combustion process, generally operate at lower noise levels. Other operational considerations include starting capabilities, load response, and altitude performance. Diesel generators typically offer excellent starting capabilities, even in cold weather conditions. Gas generators may require preheating in extremely cold environments. Load response, the ability to quickly respond to changes in electrical demand, is generally comparable between the two types of generators. Altitude performance can be affected by the availability of oxygen, and both types of generators may require adjustments or derating at high altitudes. Selecting a generator that meets the specific operational requirements of the application is crucial for optimal performance.

Specific Industrial Applications

The ideal choice between gas and diesel generator sets often depends on the specific industrial application. For critical applications requiring high reliability and continuous power, such as hospitals and data centers, diesel generators are often preferred due to their robust performance and fuel efficiency. In industries with access to natural gas pipelines, such as manufacturing plants and commercial buildings, gas generators can be a cost-effective and environmentally friendly option. Remote locations with limited access to fuel infrastructure may favor diesel generators due to the widespread availability of diesel fuel. Renewable energy projects, such as solar and wind farms, may utilize gas generators fueled by biogas to provide backup power and grid stabilization. For instance, a large agricultural operation might use a biogas-fueled generator, powered by waste products, to generate both electricity and heat, achieving impressive levels of efficiency. It all comes down to assessing the specific needs of your industry and matching them to the strengths of each generator type.

Our Solutions for Your Power Needs

At our company, we understand the complexities of choosing the right generator set for your industrial needs. We offer a comprehensive range of both gas and diesel generator sets, designed to meet the diverse requirements of various industries. Our team of experts can assist you in evaluating your power needs, conducting a thorough cost analysis, and selecting the optimal generator set for your specific application. We also provide comprehensive maintenance and service support to ensure the long-term reliability and performance of your generator set. Furthermore, we are committed to providing environmentally responsible solutions, offering generator sets with advanced emission control systems to minimize your environmental impact. By partnering with us, you can be confident that you are making a well-informed decision that aligns with your business goals and sustainability objectives. Frankly speaking, navigating the complexities of industrial power can be daunting, but we're here to simplify the process and provide you with the best possible solution.

For more detailed information, please visit our official website: https://www.hsgeneratorset.com