The concept of parallel power architecture, specifically when applied to synchronizing multiple diesel generators for critical loads, is a game-changer in ensuring uninterrupted power supply. It's more than just hooking up a few generators together; it's a sophisticated system designed to provide redundancy, scalability, and efficiency. In essence, we're talking about creating a power grid on a smaller, localized scale, tailored to meet the demanding needs of facilities where power outages are simply not an option. Think hospitals, data centers, or even large manufacturing plants – these are the kinds of places where a parallel power architecture truly shines. Have you ever wondered how these facilities manage to keep the lights on, even when the grid goes down? The answer often lies in the clever implementation of synchronized diesel generators.

Understanding the Core Principles

At the heart of parallel power architecture lies the principle of redundancy. Instead of relying on a single, large generator, multiple smaller generators are used. This means that if one generator fails, the others can pick up the load, preventing a complete power outage. It's like having multiple backup quarterbacks ready to step in if the starter gets injured. But it goes beyond simple redundancy. The synchronization aspect is equally crucial. The generators must operate in perfect harmony, sharing the load equally and maintaining a stable voltage and frequency. This requires sophisticated control systems and communication protocols to ensure that all generators are "talking" to each other and responding appropriately to changes in load demand. Furthermore, the architecture allows for scalability. As the power needs of a facility grow, additional generators can be easily added to the parallel system, providing a cost-effective and flexible solution for future expansion. This is far more manageable than replacing a single large generator with an even larger one.

The Synchronization Process: A Deeper Dive

The process of synchronizing multiple diesel generators is a complex dance of electrical engineering. It involves matching the voltage, frequency, and phase angle of each generator before connecting them to a common bus. If these parameters are not perfectly aligned, connecting the generators can result in catastrophic damage. Thankfully, modern control systems automate this process, continuously monitoring the generators and making adjustments as needed. These systems typically use sophisticated algorithms to predict and compensate for changes in load demand, ensuring a smooth and seamless transition between generators. It's worth noting that the communication between the generators is just as important as the synchronization process itself. The generators must be able to share information about their operating status, load levels, and any potential faults. This allows the system to make informed decisions about how to best distribute the load and respond to emergencies.

Benefits of Parallel Power Architecture

The benefits of using a parallel power architecture are numerous and compelling. First and foremost, it provides enhanced reliability. The redundancy inherent in the system ensures that a single generator failure will not disrupt power supply. This is particularly important for critical facilities where even a brief power outage can have devastating consequences. Secondly, it offers improved efficiency. By using multiple smaller generators, the system can match the power output to the actual load demand, reducing fuel consumption and minimizing emissions. This is in stark contrast to using a single large generator, which may be operating at a low load level for extended periods, resulting in wasted energy. Thirdly, it provides greater flexibility. The modular design of the system allows for easy expansion and reconfiguration. As the power needs of a facility change, the system can be adapted to meet those needs without significant disruption or expense. Frankly speaking, the flexibility offered is a huge advantage for growing organizations.

Practical Applications: Where Parallel Power Truly Excels

Parallel power architecture finds its home in a variety of critical applications. Data centers, for example, rely heavily on this technology to ensure the continuous operation of their servers and networking equipment. A power outage in a data center can result in significant financial losses and reputational damage. Hospitals are another prime example. The ability to maintain a constant power supply is crucial for life support systems, operating rooms, and other critical medical equipment. Industrial facilities, such as manufacturing plants and refineries, also benefit from parallel power architecture. A power outage in these facilities can halt production, damage equipment, and even pose a safety risk to workers. Beyond these specific examples, parallel power architecture is also being used in a growing number of other applications, including telecommunications facilities, transportation hubs, and even large commercial buildings. In my experience, these systems offer a robust and reliable solution for anyone who needs to ensure an uninterrupted power supply.

Challenges and Considerations

While parallel power architecture offers numerous advantages, it's not without its challenges. One of the biggest challenges is the complexity of the control systems required to synchronize and manage the generators. These systems must be carefully designed and configured to ensure that the generators operate in harmony and respond appropriately to changes in load demand. Another challenge is the initial cost of implementing a parallel power architecture. It requires purchasing multiple generators, as well as the necessary control systems and communication infrastructure. However, many experts agree that the long-term benefits of increased reliability, efficiency, and flexibility outweigh the initial investment. It's also important to consider the maintenance requirements of a parallel power architecture. Multiple generators require more frequent maintenance and inspections than a single large generator. However, this can be offset by the fact that the generators can be taken offline for maintenance one at a time, without disrupting the power supply.

The Role of Advanced Control Systems

Advanced control systems are the brains behind a successful parallel power architecture. These systems constantly monitor the performance of each generator, adjusting parameters like voltage, frequency, and load sharing to optimize overall system efficiency and stability. They also incorporate sophisticated algorithms for predictive maintenance, allowing operators to identify and address potential issues before they lead to downtime. Furthermore, modern control systems often integrate with building management systems (BMS) and other automation platforms, providing a comprehensive view of the entire facility's energy consumption and performance. This level of integration allows for more informed decision-making and greater control over energy costs. These systems aren't just about keeping the lights on; they're about optimizing performance, reducing costs, and ensuring long-term reliability.

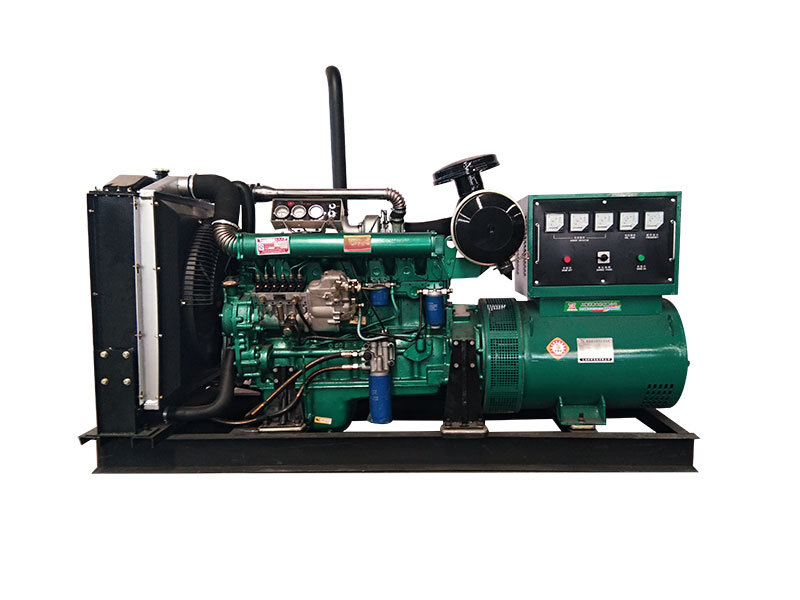

Our Solutions for Parallel Power Architecture

Our company specializes in providing comprehensive solutions for parallel power architecture, including diesel generators, control systems, and engineering services. We understand the critical importance of reliable power for various applications, and we are committed to delivering solutions that meet the highest standards of performance and dependability. Our diesel generators are designed for seamless integration into parallel systems, offering exceptional fuel efficiency, low emissions, and long service life. Our control systems are state-of-the-art, providing advanced monitoring, synchronization, and load management capabilities. We also offer a full range of engineering services, from system design and installation to commissioning and maintenance. To be honest, we pride ourselves on our ability to provide customized solutions that meet the specific needs of each customer. We work closely with our clients to understand their requirements and develop solutions that are tailored to their unique challenges. Do you need a system designed for a specific environment or load profile? We can help.

In conclusion, parallel power architecture, synchronizing multiple diesel generators for critical loads, offers a robust and reliable solution for ensuring uninterrupted power supply. Its inherent redundancy, scalability, and efficiency make it an ideal choice for facilities where power outages are simply not an option. The technology's continued advancement promises even greater levels of performance and control in the future, solidifying its role as a cornerstone of critical power infrastructure. The ability to adapt and expand power generation capacity on demand, while maintaining unwavering reliability, makes parallel power architecture a truly powerful tool.

For more detailed information, please visit our official website: https://www.hsgeneratorset.com