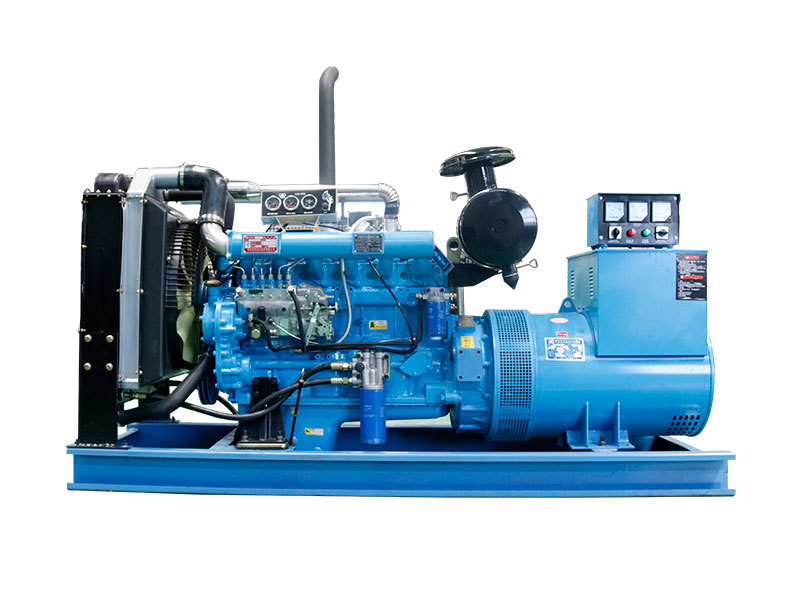

A natural gas generator set represents a sophisticated blend of mechanical and electrical engineering, designed to provide reliable power in various situations. Understanding its individual components is crucial for effective operation, maintenance, and troubleshooting. From the heart of the engine to the intricacies of the control panel, each part plays a vital role in the overall functionality of the generator set.

The engine, often referred to as the prime mover, serves as the muscle of the operation. Fueled by natural gas, this internal combustion engine converts the chemical energy of the gas into rotational mechanical energy. This rotation drives the alternator, the next critical component in the power generation process. Think of a car engine – the principles are quite similar, albeit on a larger scale, and optimized for continuous operation.

The Alternator: Converting Mechanical Energy to Electricity

The alternator is the component responsible for the magical transformation from mechanical energy to electrical energy. As the engine rotates the alternator's shaft, a magnetic field is created, inducing a voltage in the stator windings. This voltage generates the electrical current that powers our homes, businesses, or critical equipment. The alternator’s output is typically alternating current (AC), which is then regulated to provide a stable and consistent power supply.

The control system acts as the brains of the generator set. It monitors and regulates various parameters, ensuring smooth and efficient operation. This sophisticated system can automatically start and stop the generator based on power demand, monitor engine temperature and oil pressure, and protect the unit from potential faults. Modern control systems often include digital displays and remote monitoring capabilities, offering greater control and convenience.

Fuel System: Delivering the Energy Source

The fuel system ensures a consistent supply of natural gas to the engine. This system includes components such as the gas pressure regulator, fuel filter, and mixing valve. The regulator maintains the correct gas pressure for optimal combustion, while the filter removes impurities that could damage the engine. The mixing valve combines the natural gas with air in the correct proportions for efficient and clean burning.

The cooling system prevents the engine from overheating, which can lead to significant damage. Typically using a combination of coolant, radiator, and fan, this system dissipates the heat generated during combustion. Proper cooling system maintenance, including regular coolant checks and cleaning, is essential for long-term generator reliability.

Exhaust System: Managing Emissions

The exhaust system safely channels the exhaust gases produced during combustion away from the generator and the surrounding environment. This system typically includes a muffler to reduce noise levels and, in some cases, catalytic converters to minimize harmful emissions. Regulations regarding exhaust emissions vary by location, so ensuring compliance with local codes is critical.

The starting system provides the initial power needed to crank the engine and initiate combustion. Smaller generators often use an electric starter motor similar to those found in cars, while larger units might utilize compressed air or a smaller auxiliary engine. The choice of starting system depends on the size and application of the generator.

Lubrication System: Keeping Things Running Smoothly

The lubrication system ensures all moving parts within the engine are properly lubricated, reducing friction and wear. This system includes an oil pump, oil filter, and oil pan. Regular oil changes, as specified by the manufacturer, are crucial for maintaining engine health and extending the generator’s lifespan. What kind of oil should be used? That depends on the engine specifications and the operating environment.

Housing and Frame: Providing Protection and Stability

The housing and frame provide structural support and protection for all the generator components. They also help to reduce noise levels and protect against weather elements. The housing can range from a simple open frame for stationary units to weatherproof enclosures for portable generators.

Monitoring and Protection: Ensuring Safe Operation

Modern natural gas generator sets include various safety features and monitoring systems. These systems can detect potential problems, such as low oil pressure or high engine temperature, and automatically shut down the generator to prevent damage. They also often include alarms to alert operators to potential issues. How can you ensure your monitoring system is functioning correctly? Regular testing and maintenance are key.

Understanding the components of a natural gas generator set empowers owners and operators to effectively maintain, troubleshoot, and optimize their equipment. From the engine’s powerful combustion to the control system's intricate management, each part contributes to the reliable delivery of power. By appreciating the complexities of these interconnected systems, we can ensure consistent performance and maximize the lifespan of our natural gas generators.