Choosing the right power source for a construction site is a critical decision impacting productivity, cost-effectiveness, and overall project success. Two primary options typically considered are mobile generator sets and fixed generator sets. Each offers distinct advantages and disadvantages, making the optimal choice heavily dependent on the specific demands and characteristics of the construction project. Understanding these nuances is vital for project managers and contractors aiming to minimize downtime, maximize efficiency, and ensure a reliable power supply throughout the construction lifecycle. This analysis delves into the key factors influencing this decision, exploring aspects like portability, power output, environmental impact, maintenance requirements, and cost considerations associated with each type of generator.

Portability and Site Accessibility

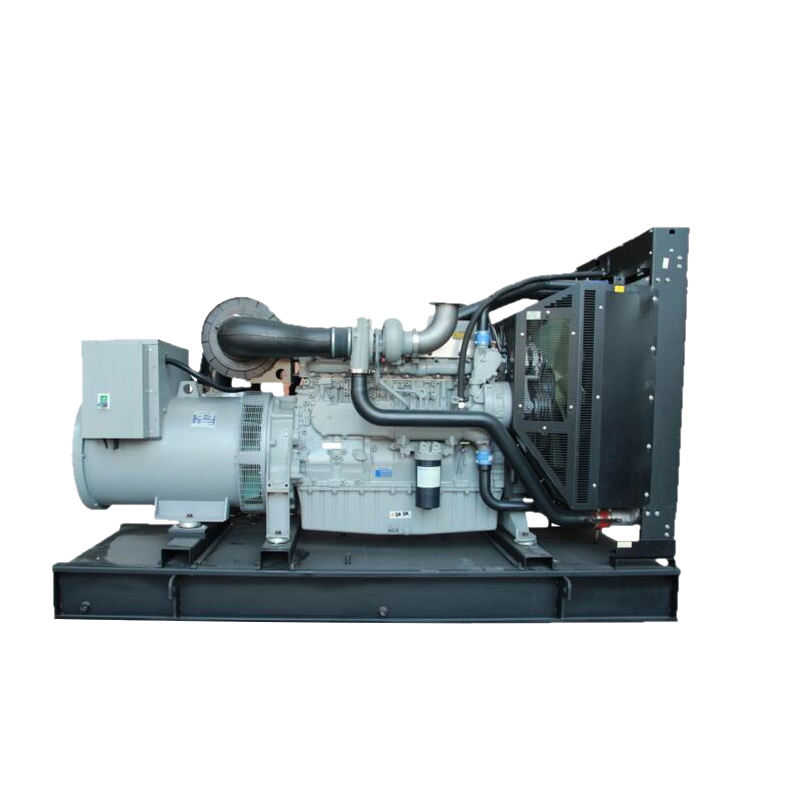

The core differentiating factor between mobile and fixed generator sets lies in their portability. Mobile generator sets are designed for easy transport, often mounted on trailers or skids, enabling them to be quickly relocated within a construction site or moved between different project locations. This is particularly advantageous for projects with phased development across a large area, or when the power needs shift as construction progresses. Consider a road construction project, where the power source needs to move along with the paving crew. A mobile generator is the clear choice here. The inherent flexibility of mobile units allows for adaptive power management, ensuring that electricity is available precisely where and when it is needed. However, their portability can sometimes come at the cost of lower power output compared to larger, stationary units. It's a trade-off that requires careful consideration based on the project's specific energy requirements.

Power Output and Scalability

While mobile generators offer the advantage of portability, fixed generator sets generally provide higher power output and better scalability. Fixed units are typically larger and more powerful, capable of supporting heavy-duty equipment and processes requiring significant electricity. They are well-suited for construction sites with substantial and consistent power demands, such as those involving high-rise buildings or large infrastructure projects. Furthermore, fixed generators often allow for easier integration with backup power systems, ensuring uninterrupted operation during grid outages. Scalability is another key advantage; fixed units can often be configured to meet increasing power demands as the project progresses. But consider this: If a site's layout means multiple, smaller power sources can reach areas a single, powerful generator can't, is that scalability actually as valuable? The answer is often a resounding no. Therefore, choosing between power output and scalability requires considering these factors.

Cost Considerations: Purchase, Operation, and Maintenance

The financial implications of choosing between mobile and fixed generator sets extend beyond the initial purchase price. While mobile units may have a lower upfront cost, the total cost of ownership encompasses operational expenses, such as fuel consumption and maintenance, as well as potential transportation costs. Fixed generator sets typically involve higher initial investment but may offer lower long-term operating costs due to their greater efficiency and longer lifespan. Maintenance is another crucial aspect. Mobile generators, due to their frequent relocation and exposure to varying environments, may require more frequent maintenance and repairs. Fixed units, on the other hand, are generally easier to maintain in a controlled environment. A comprehensive cost analysis, factoring in all these variables, is essential for making a financially sound decision. Don't forget to factor in the cost of potential downtime associated with either type, and how that downtime may vary. For example, could a fixed generator issue stop a larger portion of your site than a mobile one?

Environmental Impact and Regulations

Construction sites are under increasing scrutiny regarding their environmental impact, and generator selection plays a significant role in minimizing emissions and adhering to regulations. Both mobile and fixed generator sets are subject to emission standards, but the type of fuel used and the efficiency of the engine can significantly affect their environmental footprint. Modern generators are often equipped with advanced emission control technologies to reduce harmful pollutants. Furthermore, noise pollution is a concern, particularly in urban areas, and sound attenuation features are crucial for minimizing disturbance to the surrounding community. Choosing a generator that meets or exceeds local environmental regulations and incorporates noise reduction measures is not only responsible but can also prevent costly fines and project delays. Do you know the specific noise restrictions for your project's location?

Fuel Efficiency and Fuel Storage

Fuel consumption is a major operational expense for both mobile and fixed generator sets, and optimizing fuel efficiency is crucial for reducing costs and minimizing environmental impact. Fixed generators, due to their larger size and potential for integration with fuel storage systems, often allow for bulk fuel purchases and storage, which can lead to significant cost savings. Mobile units, on the other hand, typically rely on smaller, portable fuel tanks, which may require more frequent refueling and potentially higher fuel costs. Fuel type is another important consideration. Diesel is the most common fuel, but alternative fuels like natural gas or propane may be viable options depending on availability and cost. Selecting a generator with optimized fuel efficiency and implementing efficient fuel management practices can significantly reduce operating expenses and improve the overall profitability of the construction project.

Security and Site Safety

Security and safety are paramount considerations on any construction site, and generator sets, whether mobile or fixed, require specific security measures to prevent theft, vandalism, and accidents. Mobile generators, due to their portability, are more vulnerable to theft and require robust security measures, such as fencing, alarms, and GPS tracking. Fixed generators, while less susceptible to theft, require protection from vandalism and unauthorized access. Safety is equally important, and generators should be equipped with appropriate safety features, such as emergency shut-off switches, grounding systems, and fire suppression systems. Regular inspections and maintenance are essential to ensure the safe and reliable operation of the generator. Implementing a comprehensive security and safety plan is crucial for protecting the generator, preventing accidents, and ensuring the smooth operation of the construction site.

Specific Construction Applications

The choice between mobile and fixed generators often depends on the specific applications within a construction site. For tasks requiring temporary power in different locations, such as welding, lighting, or powering small tools, mobile generators are ideal. They can be easily moved to the point of use, providing convenient and flexible power. On the other hand, for applications requiring sustained power for heavy equipment, such as cranes, concrete mixers, or large power tools, fixed generators are more suitable. They can provide a reliable and stable power supply for extended periods. Moreover, fixed generators are often used to power site offices, workshops, and other permanent facilities on the construction site. Analyzing the power requirements of each application and selecting the appropriate generator type is crucial for optimizing efficiency and minimizing downtime.

Remote Monitoring and Management

Modern generator technology offers advanced remote monitoring and management capabilities that can significantly improve operational efficiency and reduce maintenance costs. Both mobile and fixed generator sets can be equipped with remote monitoring systems that provide real-time data on performance parameters, such as fuel consumption, engine temperature, and power output. This data allows for proactive maintenance, early detection of potential problems, and optimized fuel management. Remote start/stop functionality is another valuable feature that enables remote control of the generator, reducing the need for on-site personnel. Investing in generators with remote monitoring and management capabilities can significantly improve the overall efficiency and reliability of the power supply on the construction site. Are you currently using remote monitoring systems for your generators, and if so, what benefits have you observed?

Integrating with Renewable Energy Sources

As construction sites become increasingly focused on sustainability, integrating generator sets with renewable energy sources, such as solar panels or wind turbines, is becoming more common. Fixed generator sets are generally easier to integrate with renewable energy systems, as they can be connected to the grid and used to supplement renewable power generation. Mobile generators can also be integrated with renewable energy sources, but the logistics are more complex. A hybrid power system, combining generator sets with renewable energy sources, can significantly reduce fuel consumption, emissions, and overall environmental impact. This approach not only aligns with sustainability goals but can also lead to long-term cost savings. Considering the potential for integrating with renewable energy sources is an important aspect of generator selection for modern construction sites.

Making the Right Choice: A Summary

Ultimately, the decision between mobile and fixed generator sets for construction sites is a multifaceted one, contingent on a thorough evaluation of the project's specific needs, priorities, and constraints. Mobile generators offer unparalleled portability and flexibility, making them ideal for projects with dispersed power needs or frequent relocation requirements. Fixed generators, on the other hand, provide higher power output, scalability, and often lower long-term operating costs, making them suitable for projects with substantial and consistent power demands. By carefully considering factors such as portability, power output, cost, environmental impact, security, and integration with renewable energy sources, project managers and contractors can make an informed decision that optimizes efficiency, minimizes downtime, and ensures a reliable power supply throughout the construction lifecycle.

`