When considering power generation solutions, diesel generator sets (gensets) offer a reliable and robust option, particularly for applications demanding consistent performance in challenging environments. However, a crucial decision arises: choosing between air-cooled and liquid-cooled diesel generator sets. The cooling system significantly impacts the generator's performance, lifespan, maintenance requirements, and overall suitability for specific applications. Understanding the nuances of each system is paramount for making an informed decision that aligns with your power needs and operational constraints. This detailed comparison explores the core differences, advantages, and disadvantages of air-cooled and liquid-cooled diesel gensets, providing you with the knowledge to select the optimal solution for your specific requirements. Are you ready to delve into the specifics and determine which cooling method is best for your situation?

Understanding Air-Cooled Diesel Generator Sets

Air-cooled diesel generator sets utilize ambient air to dissipate heat generated during the combustion process. This is achieved through strategically placed fins on the engine cylinders and cylinder head, increasing the surface area available for heat transfer. A fan, typically driven directly by the engine, forces air across these fins, carrying heat away from the engine block. This design simplicity translates to several advantages. Firstly, air-cooled engines generally have fewer components compared to their liquid-cooled counterparts, reducing the potential for breakdowns and simplifying maintenance procedures. There's no need for radiators, water pumps, coolant hoses, or thermostats, contributing to a lighter and more compact design, often a crucial factor in portable generator applications. This makes them ideal for remote locations or applications where space is at a premium. However, this simplicity comes with limitations. Air-cooled systems are less efficient at dissipating heat than liquid-cooled systems, making them more susceptible to overheating, especially in high ambient temperatures or under heavy loads. How important is portability versus consistent high-load performance in your situation?

Understanding Liquid-Cooled Diesel Generator Sets

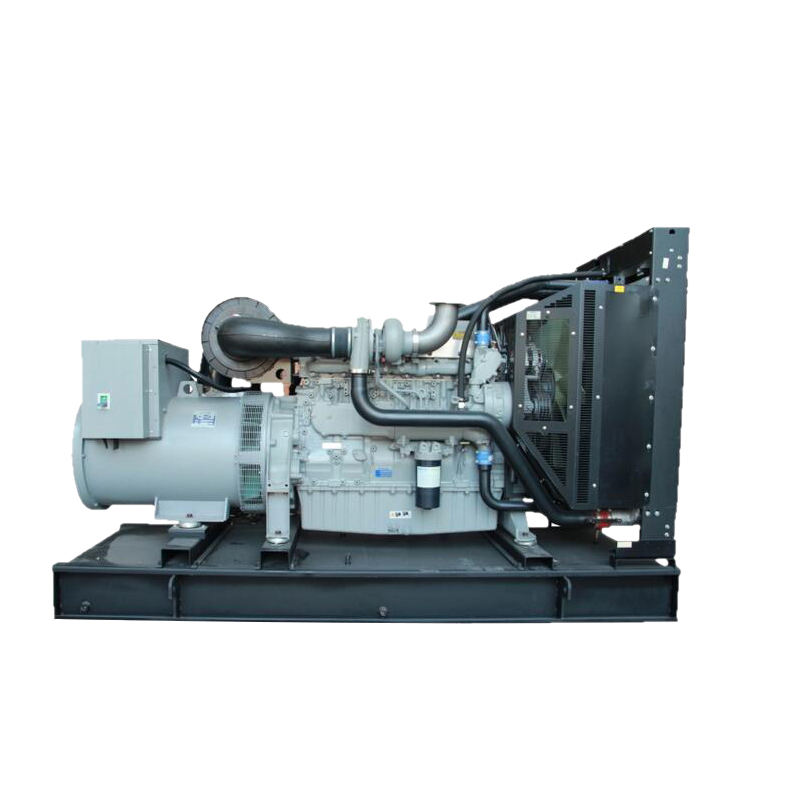

Liquid-cooled diesel generator sets, on the other hand, employ a closed-loop cooling system that circulates a coolant mixture (typically water and antifreeze) through channels within the engine block and cylinder head. This coolant absorbs heat from the engine and is then pumped to a radiator, where it dissipates the heat to the surrounding air. A fan, usually electrically driven, forces air across the radiator to enhance heat transfer. The system also includes a thermostat to regulate the coolant temperature and ensure optimal engine performance. This method provides significantly more efficient heat dissipation compared to air-cooling. Liquid-cooled generators can maintain a more consistent operating temperature, even under heavy loads and in high ambient temperatures, leading to improved engine performance and longevity. The consistent temperature also helps maintain closer tolerances within the engine, reducing wear and tear on critical components. But the increased complexity translates to higher initial costs and more intricate maintenance requirements. Regular coolant checks, radiator maintenance, and potential repairs to pumps and hoses are necessary to keep the system running efficiently.

Performance and Efficiency Considerations

When comparing the performance and efficiency of air-cooled and liquid-cooled diesel generator sets, heat management plays a pivotal role. Liquid-cooled systems consistently outperform air-cooled systems in demanding conditions due to their superior heat dissipation capabilities. The ability to maintain a lower and more stable operating temperature allows the engine to run more efficiently, optimizing fuel combustion and reducing harmful emissions. This is particularly important for continuous-duty applications where the generator operates for extended periods under high load. Air-cooled systems, while less efficient at heat management, can still provide adequate performance in less demanding applications or environments with lower ambient temperatures. However, it's crucial to consider derating the generator's output capacity in hotter climates to prevent overheating and potential damage. Derating involves reducing the maximum power output to compensate for the reduced cooling efficiency. This means an air-cooled generator rated for a certain power output might deliver less power in a hot environment compared to a liquid-cooled generator of the same rating. Are you accounting for potential derating factors in your generator selection process?

Maintenance and Longevity

The cooling system directly impacts the maintenance requirements and overall lifespan of a diesel generator set. Air-cooled systems, with their fewer components, generally require less frequent and less complex maintenance. There are no coolant leaks to worry about, no radiator to clean, and no water pump to replace. Regular maintenance primarily involves cleaning the cooling fins to ensure adequate airflow and inspecting the fan for damage. Liquid-cooled systems, on the other hand, demand more diligent maintenance. Regular coolant level checks, coolant flushes, and radiator cleaning are essential. The water pump and thermostat also require periodic inspection and potential replacement. While liquid-cooled systems require more maintenance, the consistent operating temperature they maintain can contribute to a longer engine lifespan. By preventing overheating and reducing thermal stress on engine components, liquid cooling can significantly extend the time between major overhauls. Conversely, frequent overheating in air-cooled engines can accelerate wear and tear, potentially shortening the engine's lifespan, especially if pushed to maximum capacity frequently. How important is long-term durability versus minimized maintenance efforts in your decision?

Cost Analysis: Initial Investment and Operational Expenses

The initial investment for an air-cooled diesel generator set is typically lower than that of a comparable liquid-cooled unit. This is primarily due to the simpler design and fewer components involved in the air-cooling system. However, the overall cost picture extends beyond the initial purchase price. Operational expenses, including fuel consumption, maintenance costs, and potential repair bills, must also be considered. While air-cooled generators may have lower maintenance costs in some cases, their higher fuel consumption due to lower thermal efficiency can offset these savings over the long term. Furthermore, the potential for premature engine wear and tear due to overheating can lead to more frequent and costly repairs, eroding any initial cost advantage. Liquid-cooled generators, despite their higher upfront cost, can offer lower operational expenses in the long run, especially in continuous-duty applications. Their improved fuel efficiency and longer engine lifespan can translate to significant cost savings over the generator's service life. A thorough cost analysis, considering both initial investment and long-term operational expenses, is crucial for making an economically sound decision.

Application-Specific Suitability

The ideal choice between air-cooled and liquid-cooled diesel generator sets often hinges on the specific application and operating environment. Air-cooled generators are well-suited for portable applications, such as powering construction sites, providing backup power for small businesses, or serving as emergency generators for residential use. Their lighter weight and compact size make them easy to transport and maneuver. They are also a good option for intermittent use in areas with moderate climates. Liquid-cooled generators are better suited for applications demanding continuous or heavy-duty power, such as hospitals, data centers, manufacturing plants, and large commercial buildings. Their ability to maintain a stable operating temperature under prolonged use ensures reliable power delivery and prevents costly downtime. They are also the preferred choice for environments with high ambient temperatures or heavy dust conditions, where efficient heat dissipation is crucial. Consider the typical load demand, operating hours, and environmental conditions when evaluating the suitability of each cooling system. Would you prioritize reliability under heavy load or portability for infrequent use?

Noise Levels and Environmental Impact

Another aspect to consider is the noise level produced by each type of generator set. Generally, air-cooled diesel generators tend to be noisier than liquid-cooled models. The fan used to force air across the engine's cooling fins creates a significant amount of noise, which can be a concern in noise-sensitive environments, such as residential areas or hospitals. Liquid-cooled generators, with their enclosed cooling system and often sound-attenuating enclosures, typically operate at lower noise levels. The electrically driven fan in a liquid-cooled system can also be controlled to adjust the cooling capacity and noise output based on the engine's load and temperature. Regarding environmental impact, both types of generator sets produce emissions, but liquid-cooled generators generally offer better fuel efficiency, leading to lower overall emissions per kilowatt-hour of electricity generated. Furthermore, the consistent operating temperature of liquid-cooled engines promotes more complete combustion, reducing the emission of harmful pollutants. Choosing a generator with appropriate emissions controls and considering the environmental impact of your power generation solution is increasingly important.

Summary: Making the Right Choice

In conclusion, the choice between air-cooled and liquid-cooled diesel generator sets depends on a careful evaluation of your specific needs, operating conditions, and budget constraints. Air-cooled generators offer simplicity, portability, and lower initial costs, making them suitable for intermittent use in moderate climates. Liquid-cooled generators, on the other hand, provide superior performance, efficiency, and longevity, making them the preferred choice for continuous-duty applications in demanding environments. By considering factors such as load demand, operating hours, ambient temperature, maintenance requirements, and budget, you can make an informed decision that ensures reliable and cost-effective power generation for your specific application. Ultimately, understanding the nuances of "Air-Cooled vs. Liquid-Cooled Diesel Generator Sets" allows you to power your world efficiently and effectively.

`