The question of "Diesel vs. Natural Gas Generator Sets: Which is Better?" is a crucial one for anyone needing reliable backup or primary power. Whether you're a hospital administrator, a construction site manager, or a homeowner looking to safeguard against power outages, understanding the nuances of each fuel type is paramount. This isn't a simple A versus B comparison; it's a multifaceted evaluation encompassing cost, efficiency, environmental impact, and application-specific considerations. The ideal choice hinges on a careful analysis of your unique power needs, budget constraints, and long-term operational goals. Before diving deeper, it's important to establish that both diesel and natural gas generators are robust and dependable technologies, capable of providing vital electricity in various situations. The "better" option isn't inherently superior, but rather, the one that best aligns with your specific requirements.

Understanding the Fundamentals: Diesel and Natural Gas Generators

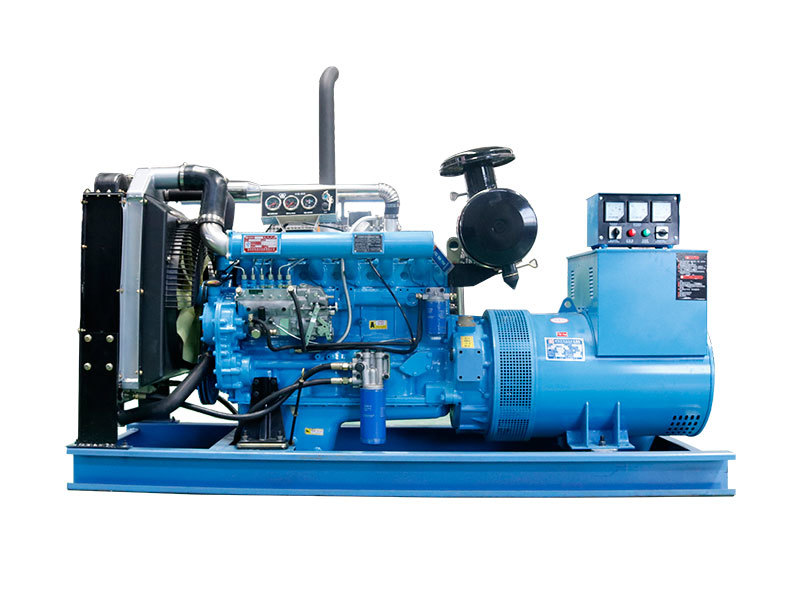

To make an informed decision, we need to delve into the core mechanics and characteristics of each generator type. Diesel generators operate on the principle of compression ignition. Air is compressed to a high degree, raising its temperature significantly. Diesel fuel is then injected into the hot compressed air, causing spontaneous combustion and driving the engine. This combustion process generates mechanical energy, which is then converted into electrical energy via an alternator. Their strength lies in their robustness and ability to handle sudden load changes. Natural gas generators, on the other hand, utilize a spark-ignition engine, similar to those found in gasoline-powered vehicles. Natural gas and air are mixed, compressed, and then ignited by a spark plug. The resulting combustion drives the engine, which in turn powers the alternator. One of the key distinctions between the two lies in fuel sourcing. Diesel fuel needs to be stored on-site, typically in tanks, while natural gas can often be supplied directly from a utility pipeline, eliminating the need for on-site storage. This difference can significantly impact logistical considerations and potential hazards associated with fuel management. Which fuels do you think are more suited for your environment and needs?

Cost Analysis: Initial Investment vs. Long-Term Expenses

The economic aspect of generator selection is often a primary driver of the decision-making process. Initially, diesel generators typically have a lower upfront purchase price compared to natural gas generators of comparable size and power output. This can be an attractive factor for projects with tight budgets. However, the initial investment is only part of the story. The long-term operating costs, including fuel consumption, maintenance, and potential repairs, need to be factored in. Diesel fuel prices tend to fluctuate more than natural gas prices, influenced by global market dynamics and geopolitical events. Natural gas, particularly in regions with abundant domestic production, can offer more price stability. Maintenance costs for diesel generators can sometimes be higher due to the complexity of the engine and the need for regular fuel filter replacements and oil changes. While natural gas generators may have simpler maintenance requirements, they might require more frequent spark plug replacements. Therefore, a thorough cost-benefit analysis, considering both initial expenses and ongoing operational costs, is essential for determining the most economically viable option.

Efficiency and Performance: Power Output and Fuel Consumption

Efficiency, in the context of generator sets, refers to the ratio of electrical energy output to the energy content of the fuel consumed. Diesel generators generally exhibit higher fuel efficiency compared to natural gas generators. This means that for the same amount of power generated, a diesel generator will consume less fuel. This can translate into significant cost savings over the lifespan of the generator, especially in applications requiring continuous or frequent operation. Power output is another critical performance parameter. Both diesel and natural gas generators can be designed to deliver a wide range of power outputs, from a few kilowatts to several megawatts. However, diesel generators tend to be more readily available in higher power ratings, making them suitable for large-scale industrial and commercial applications. Furthermore, diesel generators typically have better transient response, meaning they can quickly and effectively handle sudden increases in load demand. This is particularly important in applications where power fluctuations can disrupt sensitive equipment or processes.

Environmental Considerations: Emissions and Sustainability

Environmental impact is an increasingly important consideration in generator selection. Diesel generators are known to produce higher levels of particulate matter (PM) and nitrogen oxides (NOx) emissions compared to natural gas generators. These pollutants contribute to air pollution and can have adverse health effects. Natural gas, when burned, produces significantly lower levels of PM and NOx emissions. However, natural gas generators do emit methane (CH4), a potent greenhouse gas. Methane has a much higher global warming potential than carbon dioxide (CO2) over a shorter time horizon. The debate around the environmental superiority of one fuel over the other is complex and depends on various factors, including the efficiency of the generator, the quality of the fuel, and the presence of emission control technologies. Modern diesel generators equipped with advanced emission control systems can significantly reduce PM and NOx emissions, making them more environmentally friendly. Similarly, efforts are underway to minimize methane leakage from natural gas infrastructure and to develop natural gas generators with improved combustion efficiency.

Fuel Availability and Storage: On-Site Considerations and Logistics

One of the most significant differences between diesel and natural gas generator sets lies in the fuel source and storage requirements. Diesel fuel needs to be stored on-site in tanks, requiring space and adherence to strict safety regulations to prevent spills and leaks. The storage capacity must be sufficient to meet the anticipated power demand during outages or emergencies. Diesel fuel can also degrade over time, especially if not properly stored, potentially leading to engine problems. Natural gas, on the other hand, is often supplied directly from a utility pipeline, eliminating the need for on-site fuel storage. This simplifies logistics and reduces the risk of fuel-related hazards. However, reliance on a natural gas pipeline means that the generator is vulnerable to disruptions in the gas supply, such as pipeline failures or maintenance activities. In some areas, natural gas supply may not be readily available or may be subject to curtailments during peak demand periods. If a continuous and uninterrupted power supply is crucial, a backup fuel source, such as propane, may be necessary for natural gas generators.

Application-Specific Suitability: Matching Generators to Needs

The optimal choice between diesel and natural gas generators often depends on the specific application and its unique requirements. For instance, in remote locations where natural gas pipelines are not available, diesel generators may be the only viable option. Construction sites, mining operations, and agricultural facilities frequently rely on diesel generators due to their portability, robust performance, and ready availability of fuel. Hospitals, data centers, and telecommunication facilities, where an uninterrupted power supply is paramount, often utilize natural gas generators connected to reliable pipeline infrastructure. These facilities might also incorporate redundant power systems, such as a combination of natural gas generators and battery backup, to ensure maximum uptime. Residential applications, where space is limited and noise levels need to be minimized, may favor smaller natural gas generators that can be easily connected to existing gas lines. The decision should also consider the frequency of use. For infrequent backup power needs, the lower initial cost of a diesel generator might be more appealing. However, for continuous or frequent use, the lower fuel costs and potentially lower maintenance costs of a natural gas generator could be more advantageous.

Maintenance and Longevity: Ensuring Reliable Operation

Regular maintenance is essential for ensuring the reliable operation and longevity of both diesel and natural gas generator sets. Diesel generators require periodic fuel filter replacements, oil changes, and coolant flushes. The fuel injection system should also be inspected and cleaned regularly to prevent clogging and ensure optimal performance. Natural gas generators, while generally requiring less frequent maintenance, still need regular spark plug replacements, air filter cleaning, and engine oil changes. The gas lines and connections should also be inspected for leaks. The lifespan of a generator depends on several factors, including the quality of the equipment, the frequency of use, and the adherence to recommended maintenance schedules. Diesel generators, with their robust construction and durable engines, can often last for many years with proper care. Natural gas generators, while potentially having a slightly shorter lifespan, can still provide reliable power for an extended period. Proper sizing of the generator for the intended load is also crucial for maximizing its lifespan. Overloading a generator can lead to premature wear and tear and increase the risk of breakdowns. It is also important to keep an eye on new technological advancements that reduce carbon emission, increase efficiency and promote environmental conservation.

Looking Ahead: The Future of Generator Technology

The future of generator technology is likely to be shaped by increasing environmental concerns and the growing demand for cleaner energy solutions. Hybrid generator systems, combining diesel or natural gas generators with renewable energy sources such as solar or wind power, are gaining traction. These hybrid systems can reduce reliance on fossil fuels and lower greenhouse gas emissions. Battery storage systems are also being integrated with generators to provide instantaneous power during outages and to smooth out fluctuations in power demand. Fuel cell technology, which converts chemical energy directly into electrical energy without combustion, is another promising alternative to traditional generators. Fuel cells can operate on various fuels, including hydrogen and natural gas, and offer high efficiency and low emissions. The development of more efficient and cleaner diesel and natural gas engines is also ongoing. These engines incorporate advanced combustion technologies, such as lean-burn combustion and exhaust gas recirculation, to minimize emissions. Ultimately, the choice between diesel and natural gas generators, and the potential adoption of alternative technologies, will depend on a complex interplay of economic, environmental, and technological factors.

Making the Right Choice: A Summary

In conclusion, the debate of "Diesel vs. Natural Gas Generator Sets: Which is Better?" is far from simple. There is no one-size-fits-all answer. Diesel generators excel in portability, robustness, and ability to handle heavy loads, making them ideal for construction sites, remote locations, and applications requiring frequent portability. Natural gas generators offer advantages in fuel availability, lower emissions (excluding methane), and potentially lower operating costs, making them suitable for hospitals, data centers, and residential applications with access to reliable pipeline infrastructure. To make the right choice, you need to conduct a thorough assessment of your power needs, budget constraints, environmental considerations, and fuel availability. Consulting with a qualified generator specialist can provide valuable insights and guidance in selecting the most appropriate generator set for your specific requirements. Are you ready to weigh the pros and cons based on your specific situation? Ultimately, the "better" generator is the one that best meets your needs, ensuring a reliable and cost-effective power supply for years to come.