Gensets, short for generator sets, are indispensable power solutions, providing electricity when the main grid fails or is unavailable. Understanding the different categories of gensets is crucial for selecting the right one for a particular application. The classification of gensets hinges on several factors, ranging from the type of fuel they consume to their power output, intended use, and even their physical design. Let's delve into these categories to gain a comprehensive understanding of gensets and how they are distinguished from one another. Before we proceed though, have you considered what your primary power needs are? This will significantly influence the best genset category for you.

Fuel Type: The Energy Source

One of the most fundamental ways to categorize gensets is by the type of fuel they use. The most common types include diesel, gasoline (petrol), natural gas, propane, and even renewable sources like biogas. Diesel gensets are renowned for their durability, fuel efficiency, and ability to handle heavy loads, making them a popular choice for industrial applications and backup power for critical infrastructure like hospitals. Gasoline gensets, on the other hand, are typically smaller, more portable, and less expensive, making them suitable for residential use and smaller businesses. Natural gas gensets offer a cleaner-burning alternative and are often connected to a natural gas pipeline, providing a continuous fuel supply. Propane gensets offer similar benefits to natural gas but can be stored in tanks, offering more flexibility. Finally, biogas gensets, while less common, represent a sustainable option, utilizing biogas produced from anaerobic digestion of organic matter. Choosing the right fuel type depends on factors such as availability, cost, environmental considerations, and required power output.

Power Output: Matching the Load

Gensets are also classified by their power output, typically measured in kilowatts (kW) or megavolt-amperes (MVA). The power output dictates the amount of electrical load the genset can handle. Small, portable gensets may produce only a few kilowatts, sufficient for powering a few essential appliances during a power outage. Larger, industrial gensets can generate hundreds or even thousands of kilowatts, enough to power entire factories or even small towns. The appropriate power output is determined by carefully calculating the total power requirements of all the devices and equipment that the genset will be powering. It's crucial to select a genset with sufficient capacity to handle the peak load, including any inrush currents from motors or other inductive loads. Overestimating power requirements is generally better than underestimating, as overloading a genset can lead to damage or failure. Thinking about your future power needs, do you foresee any expansion that would require a higher capacity genset?

Application: Tailored Solutions

The intended application is another key factor in categorizing gensets. Gensets can be broadly classified into standby, prime, and continuous power categories. Standby gensets are designed to provide backup power during utility outages. They are typically used in hospitals, data centers, and other critical facilities where uninterrupted power is essential. Prime power gensets are used as the primary source of power in areas where there is no access to the utility grid or where the grid is unreliable. These are often found in remote construction sites, mining operations, and off-grid communities. Continuous power gensets are designed to operate continuously, 24 hours a day, 7 days a week. They are often used in industrial facilities and power plants to supplement the grid or provide a constant source of power. The application dictates the genset's duty cycle, required reliability, and maintenance schedule. For instance, a standby genset will have a lower duty cycle compared to a continuous power genset, and its maintenance requirements may be less frequent.

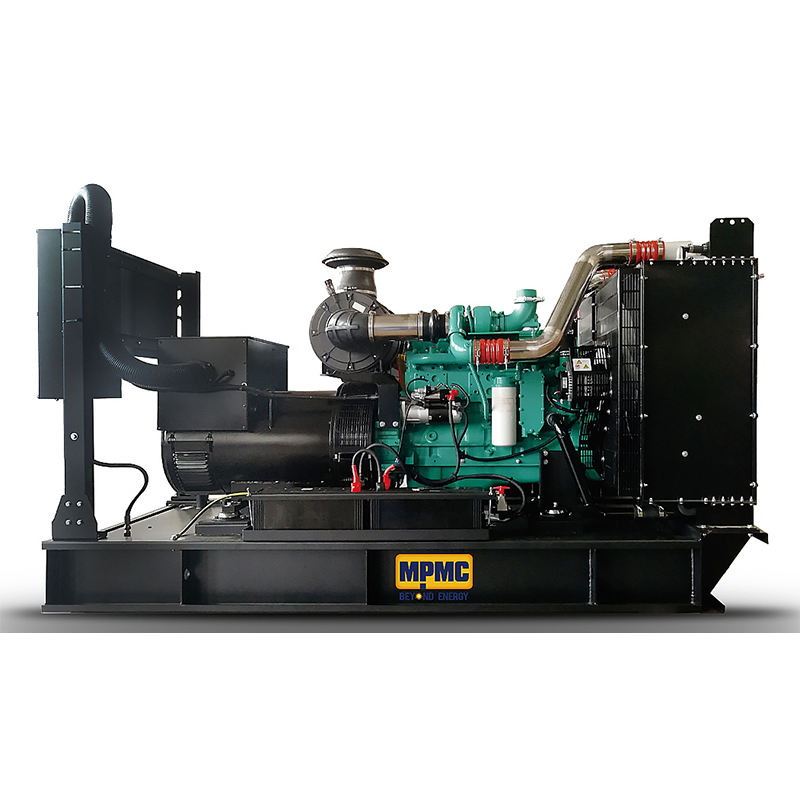

Design and Construction: Enclosed vs. Open Frame

The physical design of a genset also plays a role in its categorization. Gensets are commonly available in two main designs: enclosed and open frame. Enclosed gensets are housed within a soundproof enclosure, which reduces noise levels and protects the genset from the elements. These are often preferred in residential areas and other noise-sensitive environments. Open frame gensets, on the other hand, expose the engine and generator components. They are typically less expensive than enclosed gensets but are also noisier and more vulnerable to the elements. Open frame gensets are often used in industrial settings where noise and weather protection are less of a concern. Consider the environment where the genset will be located when choosing between enclosed and open frame designs. Will it be exposed to harsh weather conditions, or is noise a significant factor?

Portability: Stationary vs. Mobile

Another important categorization is based on portability. Stationary gensets are designed to be permanently installed in a fixed location, while mobile gensets are designed to be easily moved from one location to another. Stationary gensets are typically larger and more powerful than mobile gensets and are used in applications where a continuous source of power is required. Mobile gensets are smaller, lighter, and often mounted on trailers or skids, making them easy to transport to different job sites or emergency locations. The choice between stationary and mobile depends on the frequency with which the genset needs to be moved and the ease of access to the location where it will be used.

Phases: Single-Phase vs. Three-Phase

Electrical power can be delivered in single-phase or three-phase configurations, and gensets are categorized accordingly. Single-phase gensets are commonly used in residential and small commercial applications, where the power demand is relatively low. They provide a single alternating current (AC) voltage and are suitable for powering most household appliances and lighting. Three-phase gensets are used in industrial and large commercial applications, where the power demand is higher. They provide three separate AC voltages, which can deliver more power and are better suited for powering heavy-duty machinery and equipment. The choice between single-phase and three-phase depends on the type of electrical load and the power requirements of the application. A careful assessment of the electrical system is crucial to determine the appropriate phase configuration.

Voltage: Matching the Grid

Gensets are also categorized by their output voltage. The standard voltage varies depending on the region. For example, in North America, common voltages are 120/240V for single-phase and 208/480V for three-phase. In Europe, 230/400V is more prevalent. It’s crucial that the genset’s voltage matches the voltage requirements of the equipment it will be powering and the local grid, if applicable. Using the wrong voltage can damage equipment or result in inefficient operation. Gensets can be equipped with voltage regulators to maintain a stable output voltage, ensuring consistent performance and protecting sensitive electronic devices.

Synchronization Capability: Island vs. Grid-Tied

Finally, gensets can be categorized based on their ability to synchronize with other power sources. Island mode gensets operate independently of the utility grid, providing power to a specific load or facility. Grid-tied gensets, on the other hand, can be synchronized with the utility grid, allowing them to supply power to the grid or receive power from it. Grid-tied gensets are often used in microgrid applications, where they can supplement renewable energy sources like solar and wind power. The synchronization process requires sophisticated control systems to ensure that the genset's voltage, frequency, and phase match the grid's parameters. This categorization is important for facilities looking to either have completely independent power or want to contribute to the grid.

In conclusion, understanding the various categories of gensets – based on fuel type, power output, application, design, portability, phase, voltage, and synchronization capability – is essential for selecting the right genset for your specific needs. By carefully considering these factors, you can ensure that you choose a genset that provides reliable, efficient, and cost-effective power for your home, business, or industrial facility. What category or characteristic is most important for your specific application? Choosing wisely will save both money and headaches in the long run.