At first glance, the terms "genset" and "engine" might seem interchangeable, especially if you're not deeply involved in the world of power generation. However, understanding the distinction between them is crucial for anyone dealing with electricity supply, backup power systems, or industrial machinery. The engine is a fundamental component, the prime mover, responsible for converting fuel into mechanical energy. A genset, or generator set, on the other hand, is a complete system that utilizes an engine to generate electrical power. Think of it this way: the engine is a building block, while the genset is the entire structure built upon that block. Understanding this fundamental difference is just the beginning; there's much more to explore when comparing these two vital pieces of equipment.

The Engine: The Heart of the System

The engine itself, whether it's a diesel engine, a gasoline engine, or even a natural gas engine, is a device that converts chemical energy (from the fuel) into mechanical energy. This conversion occurs through a process of combustion, creating expanding gases that drive pistons, which in turn rotate a crankshaft. This rotating crankshaft then provides the mechanical power to drive other devices. Engines are incredibly versatile and are used in a vast array of applications, from powering vehicles and boats to driving pumps and compressors. What are some everyday examples of engines you can think of? Consider your car, your lawnmower, or even some construction equipment. Each utilizes an engine, albeit of varying sizes and capabilities, to perform its intended task. The beauty of the engine lies in its efficiency and its ability to provide a reliable source of mechanical power.

The Genset: More Than Just an Engine

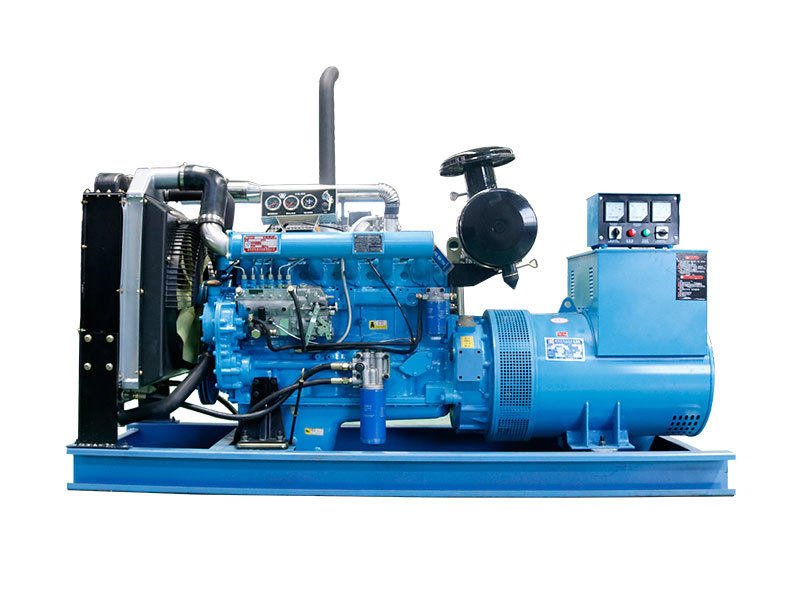

A genset, or generator set, takes the engine a step further. It's a complete system designed specifically for generating electricity. While the engine remains the core component, the genset incorporates a generator (also known as an alternator) that is directly coupled to the engine's crankshaft. This generator uses the mechanical energy produced by the engine to create electrical energy through electromagnetic induction. In simple terms, the rotating magnetic field within the generator induces a flow of electrons, resulting in an electrical current. But the genset is more than just an engine and a generator; it also includes a control panel, a cooling system, a lubrication system, a fuel system, and often an enclosure for noise reduction and weather protection. All these components work together seamlessly to provide a reliable and controlled source of electrical power.

Key Components of a Genset

Let's delve a little deeper into the key components that make up a typical genset. As we've already discussed, the engine is the prime mover, providing the mechanical energy. The generator then converts this mechanical energy into electrical energy. The control panel is the brains of the operation, monitoring various parameters such as voltage, current, frequency, and engine temperature, and providing controls for starting, stopping, and adjusting the genset's output. The cooling system, usually a radiator and fan, prevents the engine from overheating during operation. The lubrication system ensures that all moving parts within the engine are properly lubricated, reducing friction and wear. The fuel system delivers fuel to the engine in a controlled manner. Finally, the enclosure, if present, provides protection from the elements and reduces noise levels. Without any one of these systems, the genset would not be able to function effectively.

Applications of Engines and Gensets

The applications of engines and gensets are diverse and widespread, reflecting their essential roles in modern society. Engines, as standalone units, are found in virtually every mode of transportation, from cars and trucks to trains and airplanes. They also power various industrial machines, such as pumps, compressors, and agricultural equipment. On the other hand, gensets are primarily used for generating electricity in situations where grid power is unavailable or unreliable. This includes backup power for hospitals, data centers, and businesses; prime power for remote locations such as construction sites and mining operations; and temporary power for events and emergencies. Think about hospitals, for example. Their reliance on consistent power means gensets are essential to ensure vital equipment continues to function during grid outages.

The Control System: A Critical Difference

The complexity of the control system is another key differentiator between an engine and a genset. While an engine primarily requires basic controls for starting, stopping, and regulating speed, a genset necessitates a much more sophisticated control system. This system not only manages the engine's operation but also monitors and controls the generator's output, ensuring stable and reliable power delivery. Modern genset control systems often include advanced features such as automatic voltage regulation (AVR), automatic frequency regulation (AFR), and protection against overload, short circuit, and other electrical faults. Furthermore, these control systems can often be remotely monitored and controlled, allowing for proactive maintenance and troubleshooting. Without a robust control system, the genset's ability to provide consistent and reliable power would be significantly compromised.

Efficiency and Environmental Considerations

When comparing engines and gensets, it's important to consider their efficiency and environmental impact. Engines, depending on their design and application, can have varying degrees of efficiency. Factors such as combustion efficiency, friction losses, and exhaust gas temperatures all contribute to the overall efficiency of the engine. Similarly, gensets also have an overall efficiency that is determined by the engine's efficiency, the generator's efficiency, and the parasitic losses associated with the auxiliary systems. In recent years, there has been increasing focus on improving the efficiency of both engines and gensets to reduce fuel consumption and greenhouse gas emissions. This includes the development of more efficient engine designs, the use of advanced materials, and the implementation of sophisticated control strategies. What technological advances are you aware of that are helping to make engines and gensets more environmentally friendly?

Maintenance and Longevity

The maintenance requirements for engines and gensets also differ significantly. While an engine requires regular maintenance such as oil changes, filter replacements, and spark plug inspections, a genset requires more comprehensive maintenance due to its greater complexity. This includes not only the engine maintenance but also the generator maintenance, the control system maintenance, and the cooling system maintenance. Proper maintenance is crucial for ensuring the long-term reliability and performance of both engines and gensets. Neglecting maintenance can lead to premature failure, reduced efficiency, and increased downtime. Regular inspections, preventative maintenance tasks, and prompt repairs are essential for maximizing the lifespan of these valuable assets. So, while routine maintenance is important for both, the scope and complexity are significantly greater for a genset.

Cost Implications

The cost implications of purchasing and operating an engine versus a genset are substantial. An engine, being a standalone component, typically has a lower initial purchase price than a complete genset. However, the overall cost of ownership must also consider factors such as fuel consumption, maintenance costs, and potential downtime. Gensets, while more expensive upfront, offer the convenience of a complete and integrated power generation solution. The cost-benefit analysis depends heavily on the specific application and the user's requirements. For example, if you need a simple power source for a small piece of equipment, an engine might suffice. However, if you require a reliable and consistent source of electrical power for a critical application, a genset is likely the more cost-effective solution in the long run. It’s crucial to weigh all factors before making a decision.

Conclusion: Understanding the Core Difference

In summary, while an engine serves as the fundamental power source, converting fuel into mechanical energy, a genset is a comprehensive system built around an engine specifically designed for generating electrical power. The key difference lies not only in the components but also in the complexity of the system and its intended application. Understanding "What is the difference between a genset and an engine?" is crucial for making informed decisions about power generation solutions. Whether you're choosing an engine for a specific mechanical task or a genset for reliable electricity supply, appreciating these distinctions is essential.

`