Engine-driven generator sets, at their core, are machines that convert mechanical energy into electrical energy using an internal combustion engine as the prime mover. It’s a relatively straightforward concept with incredibly far-reaching applications. Consider a remote construction site where grid power is unavailable, a hospital needing backup power during an outage, or even a large event requiring temporary electricity. All of these scenarios, and countless others, rely on the dependable power provided by these essential pieces of equipment. Understanding the nuances of these generator sets, from their components to their various configurations and maintenance requirements, is crucial for anyone involved in industries where consistent and reliable power is paramount. The heart of these systems lies in the engine, but a multitude of factors play a role in the overall performance and suitability of a generator set for a specific application. So, how do you choose the right one?

Understanding the Core Components

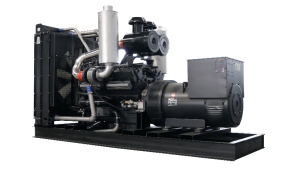

The major components of an engine-driven generator set include the engine itself, the alternator (which generates the electricity), the fuel system, cooling system, lubrication system, exhaust system, control panel, and the enclosure or housing. The engine, typically powered by diesel, gasoline, natural gas, or propane, provides the mechanical power to spin the alternator's rotor. The alternator then uses electromagnetic induction to convert this mechanical energy into alternating current (AC) electricity. The fuel system ensures a steady supply of fuel to the engine, while the cooling and lubrication systems are critical for preventing overheating and minimizing wear and tear on engine components. The exhaust system safely vents combustion gases away from the generator set and its surroundings. The control panel allows users to monitor and control the generator's operation, including starting, stopping, and monitoring key parameters like voltage, current, and frequency. All of these components are typically housed within a durable enclosure that protects them from the elements and reduces noise levels. Each component's selection and integration are vital for optimal performance and lifespan. The enclosure not only shields the generator but also contributes to noise reduction and overall safety. What are the implications of selecting a poorly sized cooling system?

Fuel Options and Considerations

The choice of fuel for an engine-driven generator set significantly impacts its operating costs, emissions, and overall suitability for a particular application. Diesel generators are generally known for their durability, fuel efficiency, and ability to handle heavy loads, making them a popular choice for industrial and commercial applications. Gasoline generators are often smaller, lighter, and less expensive upfront, but they typically have higher fuel consumption and shorter lifespans compared to diesel models. Natural gas generators offer a cleaner-burning alternative, especially when connected to a readily available natural gas pipeline. Propane generators provide a portable and relatively clean-burning option, often used in residential and smaller commercial settings. Fuel storage and handling are also important considerations, especially for diesel and propane generators, which require dedicated fuel tanks and safety protocols. The availability and cost of fuel in a particular region can also influence the choice of generator set. For instance, in areas with readily available and affordable natural gas, a natural gas generator might be the most economical option. Therefore, assessing fuel options is a crucial part of planning any generator application. How does the availability of natural gas influence the decision for a particular application?

Types of Engine-Driven Generator Sets

Engine-driven generator sets come in a variety of types, each designed to meet specific power requirements and application needs. Portable generators are small, lightweight, and easy to transport, making them ideal for camping, construction sites, and emergency backup power for homes. Standby generators are permanently installed and automatically start when a power outage is detected, providing seamless backup power for critical loads. Prime power generators are designed for continuous operation and are used in situations where grid power is unavailable or unreliable, such as remote mining operations or islands. Mobile generators are mounted on trailers or trucks, allowing them to be easily moved from one location to another, making them suitable for construction sites, events, and disaster relief efforts. The power output of generator sets ranges from a few kilowatts (kW) for small portable models to several megawatts (MW) for large industrial units. Selecting the right type of generator set depends on factors such as the power requirements, the intended application, the availability of fuel, and the desired level of automation. Each type offers a unique set of advantages and disadvantages, so careful consideration is essential.

Applications Across Industries

The versatility of engine-driven generator sets makes them indispensable across a wide range of industries. In the healthcare sector, hospitals and clinics rely on standby generators to ensure uninterrupted power for critical medical equipment and life-support systems. The telecommunications industry uses generator sets to power cell towers and data centers, maintaining connectivity even during power outages. Construction sites often rely on portable or mobile generators to power tools, lighting, and other equipment. Manufacturing plants use generator sets for both prime power and backup power, ensuring continuous production and preventing costly downtime. Emergency services use mobile generators to power field hospitals, communication centers, and other critical infrastructure during natural disasters and emergencies. Agricultural operations use generator sets for irrigation, powering farm equipment, and maintaining cold storage facilities. The ability to provide reliable power in diverse and challenging environments makes engine-driven generator sets an essential asset for many industries. How crucial is a standby generator to a hospital's operation during a blackout?

Maintenance and Longevity

Regular maintenance is essential for ensuring the reliable performance and longevity of engine-driven generator sets. A well-maintained generator set will not only operate more efficiently but will also be less prone to breakdowns and costly repairs. Recommended maintenance tasks include regular oil changes, filter replacements (air, fuel, and oil), spark plug inspections (for gasoline engines), coolant level checks, battery maintenance, and inspection of belts and hoses. It’s also important to periodically load-bank test the generator set to ensure that it can handle its rated power output. Keeping the generator clean and free from debris is also important for preventing overheating and other problems. Following the manufacturer's recommended maintenance schedule is crucial, as is keeping detailed records of all maintenance activities. Neglecting maintenance can lead to reduced performance, increased fuel consumption, and premature failure of components. Properly maintained, engine-driven generator sets can provide years of reliable service. Consider this: A small investment in preventative maintenance can save a significant amount on emergency repairs and downtime. Do you know where to find the maintenance schedule for your generator set?

Sizing Considerations: Getting the Right Fit

Properly sizing an engine-driven generator set for a particular application is crucial for ensuring optimal performance and efficiency. An undersized generator set may not be able to handle the load, leading to voltage drops, equipment malfunction, and even generator damage. An oversized generator set, on the other hand, will operate inefficiently and consume more fuel than necessary. The first step in sizing a generator set is to determine the total power requirements of all the loads that will be connected to it. This includes both continuous loads (such as lighting and computers) and intermittent loads (such as motors and air conditioners). It's also important to consider the starting currents of motors, which can be several times higher than their running currents. After calculating the total power requirements, it's recommended to add a safety factor of 20-25% to account for future growth and unexpected loads. Consult with a qualified generator set supplier or engineer to ensure that you select the right size generator set for your needs. Remember that proper sizing contributes not only to performance but also to cost-effectiveness. What are some common mistakes to avoid when sizing a generator set?

The Future of Engine-Driven Generator Sets

The field of engine-driven generator sets is constantly evolving, with advancements in technology driving improvements in efficiency, emissions, and reliability. One key trend is the increasing use of electronic engine controls, which optimize fuel injection, ignition timing, and other engine parameters for improved performance and reduced emissions. Another trend is the development of more efficient alternators, which convert mechanical energy into electrical energy with less loss. Hybrid generator sets, which combine an engine-driven generator with battery storage, are also gaining popularity, offering improved fuel efficiency and reduced noise levels. Furthermore, there's growing interest in alternative fuels such as biodiesel and renewable natural gas, which can further reduce the environmental impact of engine-driven generator sets. These advancements are making generator sets more sustainable and cost-effective, ensuring their continued relevance in a wide range of applications. The integration of smart technologies will further optimize performance. How will advancements in battery technology impact the future of generator sets?

Cost Analysis and Return on Investment

When evaluating engine-driven generator sets, it’s important to consider the total cost of ownership, not just the initial purchase price. This includes the cost of fuel, maintenance, repairs, and depreciation. Fuel costs can be a significant expense, especially for generators that are used frequently or for extended periods. Maintenance costs can be minimized by following the manufacturer's recommended maintenance schedule and using high-quality parts. Repair costs can be difficult to predict, but they can be reduced by investing in a reliable generator set from a reputable manufacturer and by performing regular maintenance. Depreciation is the decrease in value of the generator set over time. By carefully analyzing these costs, you can determine the total cost of ownership and compare different generator sets. A thorough cost analysis helps you make an informed decision and choose the generator set that offers the best return on investment for your specific needs. Remember to factor in the potential cost savings from avoiding downtime and lost productivity. Has anyone ever regretted investing in a reliable generator set?

Conclusion: The Enduring Importance of Engine-Driven Generator Sets

In conclusion, engine-driven generator sets remain a vital source of reliable power for a diverse range of applications, from providing backup power during emergencies to powering remote construction sites and critical infrastructure. Their ability to convert mechanical energy into electrical energy makes them indispensable in situations where grid power is unavailable or unreliable. While the field is continuously evolving with advancements in technology and fuel efficiency, the fundamental principle remains the same: providing a dependable power source when and where it is needed most. By understanding the core components, fuel options, types, applications, maintenance requirements, and sizing considerations, businesses and individuals can make informed decisions when selecting and operating engine-driven generator sets. The enduring importance of these machines lies in their versatility, reliability, and ability to provide a critical lifeline in a world increasingly reliant on electricity. They are a testament to the ingenuity of engineering and their continuous adaptation to meet the ever-growing demands for power.

`