Heavy-duty industrial generators stand as cornerstones of operational resilience across a multitude of sectors. These are not your average portable generators for weekend camping trips; they're engineered to provide robust, continuous, and reliable power in demanding environments where grid electricity is either unavailable, unreliable, or insufficient. The very phrase "heavy duty" speaks to their build quality, component selection, and overall design philosophy. They are built to withstand harsh conditions, prolonged usage, and significant power demands, making them indispensable for industries that cannot afford power interruptions.

Understanding the Core: Design and Functionality

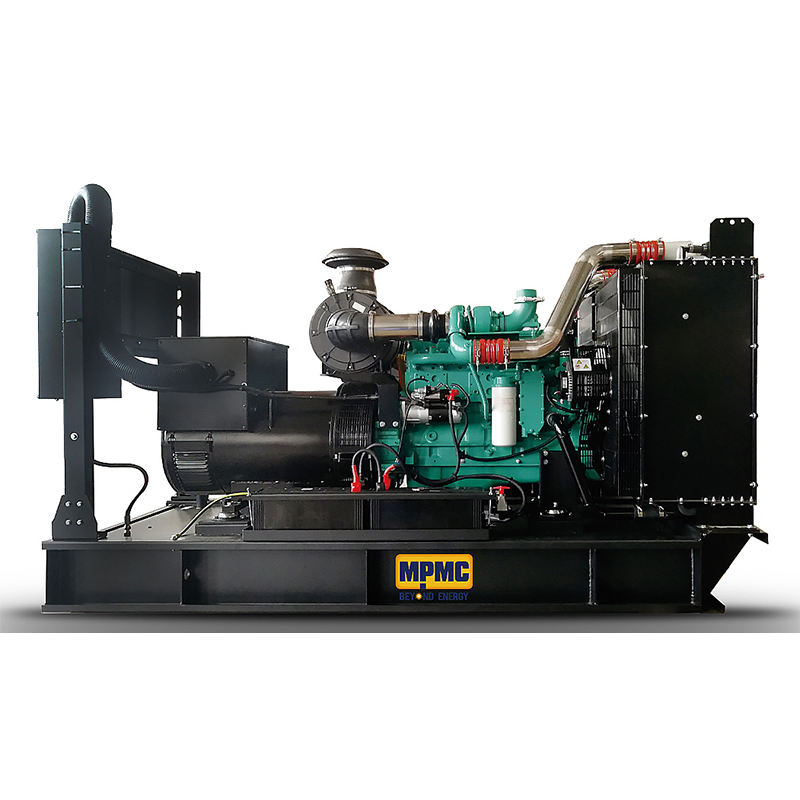

At their core, heavy-duty industrial generators operate on the principle of converting mechanical energy into electrical energy. This is most commonly achieved through an internal combustion engine – typically diesel, natural gas, or propane – that drives an alternator. The engine’s robust construction is critical; these engines are designed for longevity and consistent performance, often incorporating features like heavy-duty bearings, advanced cooling systems, and sophisticated fuel injection systems to optimize efficiency and minimize emissions. The alternator, responsible for generating the electricity, is equally important. It must be capable of handling significant loads and maintaining stable voltage and frequency outputs, even under fluctuating demand. Furthermore, advanced control systems constantly monitor and manage the generator's performance, providing critical data on parameters like voltage, current, frequency, and engine temperature. This allows for proactive maintenance and prevents potential damage or failures.

The heavy-duty nature extends beyond just the engine and alternator. The entire generator package, including the enclosure, cooling system, and control panel, is designed to withstand the rigors of industrial environments. Enclosures are typically constructed from thick steel and are often soundproofed to minimize noise pollution. Cooling systems are crucial for preventing overheating, especially during continuous operation, and may involve liquid cooling, air cooling, or a combination of both. The control panel provides a user-friendly interface for monitoring and managing the generator's performance. It often includes features such as automatic start/stop functionality, remote monitoring capabilities, and alarms for critical parameters.

Applications Across Industries

The applications for heavy-duty industrial generators are as diverse as the industries they serve. In the healthcare sector, for example, these generators are absolutely vital for maintaining life-support systems, powering operating rooms, and preserving critical medical supplies in the event of a power outage. Hospitals simply cannot function without a reliable backup power source. Similarly, data centers rely on heavy-duty generators to ensure uninterrupted operation of their servers and networks, preventing data loss and maintaining business continuity for countless organizations. Consider the financial implications of a data center outage – it's a risk no company can afford. Furthermore, manufacturing facilities utilize these generators to power production lines, ensuring continuous operation and preventing costly downtime. In remote locations, such as mining sites or oil and gas platforms, heavy-duty generators often serve as the primary power source, providing electricity for all operations and living accommodations.

Construction sites also frequently employ heavy-duty generators to power tools, equipment, and lighting, particularly in areas where grid power is unavailable or unreliable. Think about large-scale infrastructure projects – without reliable power, progress grinds to a halt. Telecommunications companies rely on generators to keep cell towers and communication networks operational, even during severe weather events. This ensures that emergency services and essential communication lines remain open. Emergency response organizations, such as fire departments and disaster relief agencies, also rely on portable heavy-duty generators to provide power for rescue operations, field hospitals, and temporary shelters.

Fuel Options and Considerations

Several fuel options are available for heavy-duty industrial generators, each with its own advantages and disadvantages. Diesel is the most common fuel source due to its high energy density, availability, and relatively low cost. Diesel generators are known for their reliability and long lifespan, making them a popular choice for critical applications. However, diesel engines can produce higher levels of emissions compared to other fuel types. Natural gas is another popular option, particularly for facilities that have access to a natural gas pipeline. Natural gas generators tend to be cleaner-burning than diesel generators and can be more cost-effective to operate, especially in areas with low natural gas prices. Propane is a versatile fuel source that can be stored in tanks, making it suitable for remote locations or emergency backup power. Propane generators are relatively clean-burning and easy to maintain. The choice of fuel depends on factors such as fuel availability, cost, emissions regulations, and operational requirements.

Beyond the immediate fuel source, factors like storage and refueling logistics must also be considered. Diesel fuel requires secure and appropriately sized storage tanks, as well as procedures for preventing spills and contamination. Natural gas requires connection to a pipeline and may involve permits and inspections. Propane tanks need to be regularly refilled and stored safely. Furthermore, fuel efficiency is a critical factor in determining the overall cost of ownership. Modern heavy-duty generators incorporate advanced fuel management systems to optimize fuel consumption and minimize waste. Regular maintenance, including fuel filter changes and engine tune-ups, is essential for maintaining optimal fuel efficiency. What measures do you currently have in place or are considering implementing to ensure fuel security and efficiency for your heavy-duty industrial generator needs?

Maintenance and Longevity

Regular maintenance is paramount to ensuring the long-term reliability and performance of heavy-duty industrial generators. A well-maintained generator will not only operate more efficiently but will also have a significantly longer lifespan. Maintenance schedules typically involve routine inspections, fluid level checks, filter replacements, and engine tune-ups. It's also crucial to monitor the generator's performance parameters, such as voltage, current, frequency, and engine temperature, to identify potential problems early on. Any unusual readings or alarms should be investigated promptly. Proper lubrication is essential for minimizing wear and tear on engine components. Oil and filter changes should be performed according to the manufacturer's recommendations. The cooling system should also be inspected regularly to ensure that it is functioning properly and that there are no leaks or blockages.

Battery maintenance is another critical aspect of generator upkeep. Batteries are essential for starting the generator, and a weak or dead battery can render the generator useless. Batteries should be regularly tested and charged to ensure that they are in good working condition. Furthermore, the generator should be exercised regularly, even if it is not needed for backup power. This helps to keep the engine lubricated and prevents components from seizing up. Load bank testing is a valuable tool for verifying the generator's ability to handle its rated load. Load bank testing involves applying a simulated load to the generator and monitoring its performance. This can help to identify any weaknesses or limitations in the generator's capacity. It is beneficial to establish a preventative maintenance program based on the manufacturer's recommendations or to contract with a qualified service provider to handle the upkeep of the generator.

Selecting the Right Generator: Key Considerations

Choosing the right heavy-duty industrial generator is a critical decision that requires careful consideration of several factors. The first step is to determine the power requirements of the equipment or facility that the generator will be powering. This involves calculating the total wattage of all the electrical loads that will be connected to the generator simultaneously. It's important to account for both continuous loads and starting loads, which can be significantly higher than continuous loads. Once the power requirements have been determined, the next step is to select a generator that is appropriately sized. It's generally recommended to choose a generator that has a capacity slightly higher than the calculated power requirements to allow for future expansion and to provide a margin of safety. The environment where the generator will be installed also plays a crucial role. Generators intended for use outdoors must be housed in weather-proof enclosures to protect them from the elements. Generators installed indoors must be properly ventilated to prevent the buildup of exhaust fumes.

Regulatory compliance is another critical consideration. Generators must comply with all applicable environmental regulations, including emissions standards and noise restrictions. It's important to choose a generator that is certified to meet these regulations. Cost is always a factor in any purchasing decision, but it's important to consider the total cost of ownership, which includes not only the initial purchase price but also the cost of fuel, maintenance, and repairs. A generator with a lower purchase price may have higher operating costs, making it less economical in the long run. What specific regulatory requirements apply to generator installations in your location, and how are you ensuring compliance?

Technological Advancements and the Future of Industrial Generators

The field of heavy-duty industrial generators is constantly evolving, with ongoing technological advancements aimed at improving performance, efficiency, and environmental impact. One significant trend is the development of more efficient engines that consume less fuel and produce fewer emissions. These engines often incorporate advanced technologies such as common rail fuel injection, variable valve timing, and turbocharging. Another trend is the increasing use of digital control systems, which provide more precise monitoring and control of generator performance. These systems can also be integrated with remote monitoring and diagnostic tools, allowing for proactive maintenance and troubleshooting. Hybrid generators, which combine a traditional engine with a battery storage system, are also gaining popularity. Hybrid generators can provide a more stable and reliable power supply, while also reducing fuel consumption and emissions.

The rise of renewable energy sources is also impacting the design and operation of heavy-duty industrial generators. Many facilities are now using generators in conjunction with solar panels or wind turbines to create microgrids, which can provide a more sustainable and resilient power supply. Smart grid technologies are also being integrated with generators to optimize power distribution and improve grid stability. Looking ahead, it's likely that heavy-duty industrial generators will become even more efficient, reliable, and environmentally friendly. As technology continues to advance, generators will play an increasingly important role in ensuring power security and business continuity in a wide range of industries. The key to successful implementation lies in carefully evaluating specific needs and selecting a generator that meets those needs in a cost-effective and sustainable manner.

The Undeniable Importance of Reliable Power

In conclusion, heavy-duty industrial generators are essential investments for any organization that requires a dependable and consistent power source. Their robust design, diverse fuel options, and advanced control systems make them ideally suited for demanding industrial environments. From healthcare facilities to data centers, manufacturing plants to remote mining operations, these generators play a vital role in ensuring business continuity and protecting critical infrastructure. The considerations for choosing, operating, and maintaining these generators are extensive, but the payoff in terms of reliability and peace of mind is undeniable. Their enduring presence in a variety of critical industries underscores their importance, solidifying their role as key players in today's energy landscape, and ensuring "Heavy duty industrial generators" remain a vital component of operational success.

`