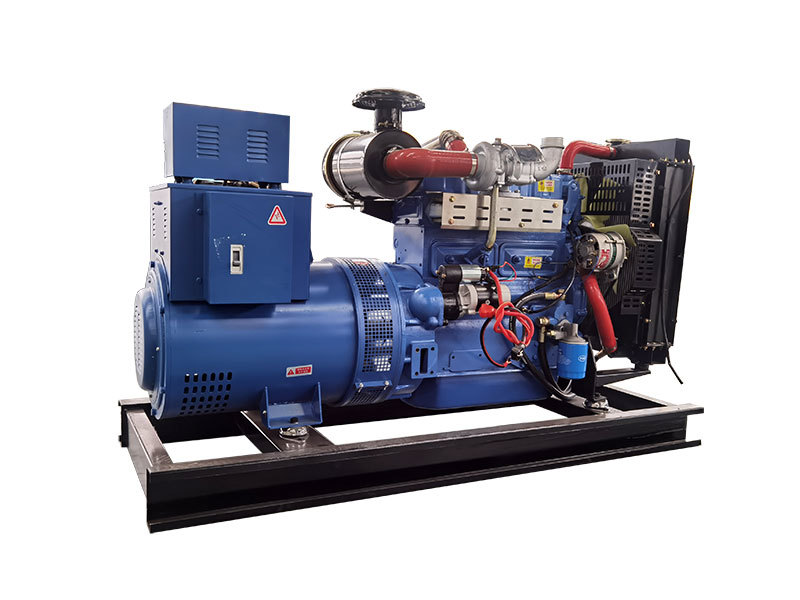

The need for reliable and continuous power is paramount across numerous industries and applications. From providing backup power during outages to serving as the primary source of electricity in remote locations, generator sets play a crucial role. However, the frequency with which a generator needs to be refueled can significantly impact its usability and operational efficiency. This is where generator sets with extended fuel tanks come into play, offering a practical and often indispensable solution for applications demanding prolonged runtime.

Understanding the Benefits of Extended Fuel Tanks

Generator sets with extended fuel tanks offer a multitude of advantages over their standard counterparts. Perhaps the most obvious benefit is the increased runtime between refueling intervals. This is particularly critical for applications where downtime is unacceptable, such as hospitals, data centers, and emergency response services. Think about a hospital during a severe storm. Every second counts. An extended fuel tank ensures that life-saving equipment remains operational without the constant worry of running out of fuel. Beyond critical infrastructure, businesses can benefit by avoiding costly interruptions to manufacturing processes or server downtime. The reduction in refueling frequency also translates to lower operational costs. Less frequent refueling means less labor, reduced transportation expenses for fuel delivery, and minimized risk of fuel spillage. Finally, extended fuel tanks contribute to improved convenience and reduced maintenance. Less frequent refueling means less wear and tear on fuel pumps and related components, potentially extending the lifespan of the generator set.

Applications Across Industries

The versatility of generator sets with extended fuel tanks allows them to be deployed across a wide range of industries and scenarios. In the telecommunications sector, cell towers and communication hubs rely on uninterrupted power to maintain network connectivity. Extended fuel tanks ensure these vital communication links remain operational even during prolonged power outages. For construction sites, especially those in remote areas, these generators provide power for tools, lighting, and other essential equipment, allowing work to continue uninterrupted. The agricultural sector relies on these generators for irrigation systems, livestock management, and powering agricultural machinery, particularly during peak seasons when power demands are high. Moreover, disaster relief efforts depend heavily on these generators to power field hospitals, communication centers, and temporary shelters in areas where the power grid is compromised. The ability to operate for extended periods without refueling is crucial in these time-sensitive situations. Consider a remote scientific research station – their existence and data rely almost entirely on a constant power source.

Key Considerations When Choosing a Generator Set with an Extended Fuel Tank

Selecting the right generator set with an extended fuel tank requires careful consideration of several factors. First and foremost is determining the required power output. This involves calculating the total wattage of all the devices and equipment that will be powered by the generator. It’s always advisable to overestimate the power needs slightly to accommodate future expansion or unexpected power surges. Next, assess the desired runtime. This depends on the application and the frequency with which refueling is possible. Consider the longest potential outage duration and choose a fuel tank capacity that provides sufficient runtime. The type of fuel used by the generator is another crucial factor. Diesel, gasoline, and natural gas are the most common options, each with its own advantages and disadvantages in terms of cost, availability, and emissions. Furthermore, evaluate the environmental conditions in which the generator will operate. Extreme temperatures, humidity, and altitude can affect the generator's performance and fuel consumption. Ensure the generator is designed to withstand these conditions. Finally, consider the noise level of the generator, especially if it will be located in a residential or noise-sensitive area. Opt for a model with noise reduction features if necessary.

Sizing and Fuel Consumption: Matching the Tank to Your Needs

Accurately sizing the extended fuel tank is crucial for optimizing performance and minimizing operational costs. Too small a tank will require frequent refueling, negating the benefits of an extended fuel capacity. Too large a tank might be unnecessary and lead to wasted space and higher upfront costs. The key to proper sizing is understanding the generator's fuel consumption rate. This is typically expressed in gallons per hour (GPH) at different load levels. The manufacturer's specifications should provide this information. Once the fuel consumption rate is known, you can calculate the required tank capacity by multiplying the desired runtime by the fuel consumption rate. For example, if a generator consumes 2 GPH and you need it to run for 72 hours, you would need a fuel tank with a capacity of at least 144 gallons. However, it's important to factor in a safety margin of around 10-20% to account for variations in fuel consumption and unexpected delays in refueling. Remember to consider factors like ambient temperature, generator load, and fuel quality, as all can impact consumption rates. Are you planning on expanding your operations in the future? Think about that extra capacity now.

Fuel Tank Materials and Construction

The materials used in the construction of the extended fuel tank play a significant role in its durability, safety, and lifespan. Steel is a common choice for larger fuel tanks due to its strength and resistance to corrosion. However, steel tanks may require protective coatings to prevent rusting, especially in harsh environments. Polyethylene (PE) tanks are another popular option, particularly for smaller to medium-sized generators. PE tanks are lightweight, corrosion-resistant, and relatively inexpensive. They are also less prone to leaks compared to steel tanks. Fiberglass tanks offer a good balance of strength, corrosion resistance, and lightweight properties. They are often used in demanding applications where durability is paramount. Regardless of the material, the fuel tank should be designed and constructed in accordance with relevant industry standards and regulations. This includes proper venting, overfill protection, and spill containment measures. The tank should also be equipped with a fuel level gauge to allow for easy monitoring of fuel levels. Furthermore, regular inspections are crucial to identify any signs of damage or corrosion, ensuring the continued safe and reliable operation of the generator set. A small leak, left unchecked, can quickly become a major hazard.

Safety Considerations for Extended Fuel Tanks

Working with fuel, especially in large quantities, necessitates strict adherence to safety protocols. Proper ventilation is essential to prevent the buildup of flammable vapors, which can create an explosion hazard. The area around the generator set and fuel tank should be well-ventilated, and any potential ignition sources, such as open flames or sparks, should be strictly prohibited. Spill containment measures are also crucial to prevent fuel spills from contaminating the environment. This includes using drip pans or containment berms around the fuel tank to capture any leaks or spills. Fire extinguishers should be readily available in the vicinity of the generator set and fuel tank. Employees or personnel operating the generator should be trained in the proper use of fire extinguishers and emergency procedures. Regular inspections of the fuel tank and fuel lines are essential to identify any signs of leaks, corrosion, or damage. Any issues should be addressed promptly to prevent fuel spills or other safety hazards. Furthermore, ensure compliance with all relevant local, state, and federal regulations regarding fuel storage and handling. Remember, complacency can be dangerous when dealing with flammable materials.

Maintenance and Longevity: Keeping Your Generator Running Smoothly

Proper maintenance is key to ensuring the longevity and reliable operation of a generator set with an extended fuel tank. Regular inspections of the fuel tank, fuel lines, and fuel filters are essential to identify any signs of leaks, corrosion, or contamination. Fuel filters should be replaced regularly to prevent debris from clogging the fuel system. The fuel itself should be stored properly to prevent degradation and contamination. This includes using a fuel stabilizer to prevent the formation of gum and varnish, especially if the generator is not used frequently. Regular engine maintenance, including oil changes, air filter replacements, and spark plug replacements (for gasoline engines), is also crucial for maintaining optimal performance and fuel efficiency. The cooling system should be inspected regularly to ensure proper coolant levels and that the radiator is free of debris. The battery should be checked and maintained to ensure reliable starting. Finally, it's always a good idea to keep a log of all maintenance activities, including dates, tasks performed, and parts replaced. This helps track the generator's maintenance history and identify any potential issues before they become major problems. Consistent upkeep is much cheaper than a complete overhaul down the line.

The Future of Generator Sets with Extended Fuel Tanks

The technology surrounding generator sets with extended fuel tanks continues to evolve, driven by the demand for increased efficiency, reduced emissions, and enhanced reliability. One area of focus is the development of more fuel-efficient engines that consume less fuel while delivering the same power output. This translates to longer runtimes and lower operational costs. Another trend is the integration of smart monitoring systems that provide real-time data on fuel levels, engine performance, and other critical parameters. These systems can alert users to potential issues before they become major problems, allowing for proactive maintenance. The use of alternative fuels, such as biodiesel and renewable natural gas, is also gaining traction as a way to reduce emissions and promote sustainability. Furthermore, advancements in fuel tank materials are leading to the development of lighter, stronger, and more corrosion-resistant tanks. These advancements are helping to make generator sets with extended fuel tanks more efficient, reliable, and environmentally friendly, ensuring they remain a vital source of power for a wide range of applications. What innovations are you most excited to see in the next generation of generators?

In conclusion, generator sets with extended fuel tanks represent a vital solution for anyone requiring a dependable and prolonged source of power. Their ability to provide uninterrupted electricity across diverse industries and applications, from emergency services to remote construction sites, highlights their practical significance. Careful consideration of power requirements, desired runtime, fuel type, and environmental factors is paramount when selecting the right generator set. Proper maintenance and adherence to safety protocols are equally crucial for ensuring longevity and reliable operation. As technology advances, we can anticipate even more efficient and environmentally friendly generator sets with extended fuel tanks, solidifying their role as an indispensable power source for the future.